- Overview

- Inquiry

- Related Products

zhongji

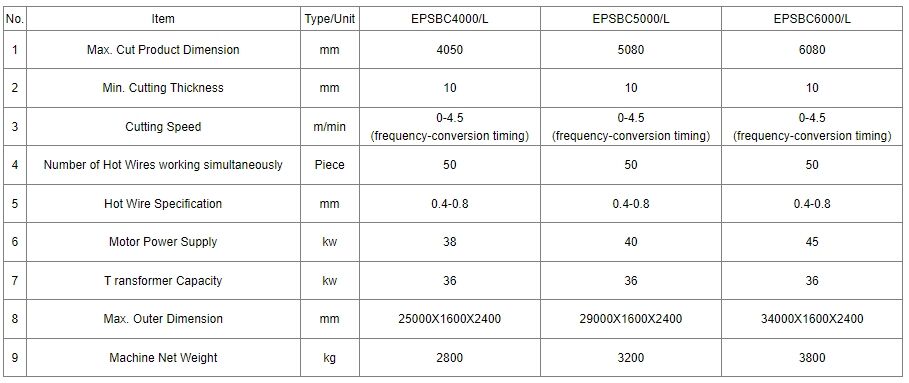

Premium Quality EPS Automatic Continuous Block Cutting Lines are the ideal solution for those who are looking for a reliable and efficient way to cut EPS blocks. These automatic cutting lines use advanced technology to cut the blocks into perfect shapes and sizes with ease.

This cutting line is designed to cut 2D or 3D blocks continuously, which means that it can cut multiple blocks of the size is same manual interventions. This feature saves some time increases efficiency, making it and choice is ideal large-scale manufacturing.

Manufactured of high-quality steel, making sure it really is durable and durable. It is also created become effortlessly changeable, which makes it simple to take care of the machine.

This automatic cutting line is also equipped with a user-friendly touch display, which enables the operator to monitor and get a handle on the cutting process with ease. The touch screen displays the equipment's status, like the rate, cutting direction, and blade position, which makes it simple for users to make adjustments as needed.

Has a design is compact making it very easy to install in smaller factories. It is also energy-efficient, this means it an affordable option for small-scale producers that it makes use of less energy than other similar machines, making.

Another great feature of this cutting line significantly different types to its compatibility of EPS materials, including graphite EPS, white EPS, and flame-retardant EPS. This helps to ensure that the device may be used for a variety of applications, from packaging to building insulation.

With Zhongji, you can be sure that you are getting a high-quality product that will help your business thrive. Get your Zhongji Premium Quality EPS Automatic Continuous Block Cutting Lines today.

EPS automatic continuous block cutting machine adopts PLC programmable industrial controller and computer touch screen. Control the motor to drive the chain drive to realize the automatic positioning and continuous walking of the EPS sheet.

Main Features

1. The machine uses the PLC (Programmable Logic Controller) and Touch Screen to achieve the automatic positioning and continuous moving of the EPS Panel. The machine controls the motor to drive the transmission chain, at the same time makes use of the resistance wires to cut out the required EPS Sheets.

2. The machine uses the Horizontal and Vertical Cutting Wires to achieve the 3D (Three-Dimensional) Cutting of the EPS Blocks.3. The machine has a specially made 10KVA Transformer with multiple sockets, to which the Horizontal Cutting frame can use 60 electric hot wires at the same time, the Vertical Cutting frame can use 20 electric hot wires at the same time. The Transformer has a large capacity, at the same time can smoothly regulate the voltage by using the voltage regulator.

4. The machine uses the Frequency-Speed Regulator that makes the speed regulation convenient, stable frequency, and to smoothly cut the EPS Blocks of stable dimensions.

5. The efficiency of this machine is 3~5 times as that of the ordinary Cutting Machine.

6. Customer can optionally select the machine for automatically collecting and crushing the side-scraps.

7. The client can choose vibrating cutting and wire auto adjusting system. The vibrating cutting can improve the cutting speed and accuration. It is especially suitable for coated EPS block cutting.

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2. The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our Company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance cannot be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ