- Overview

- Inquiry

- Related Products

zhongji

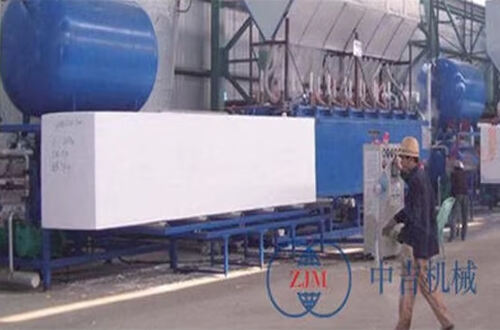

Introducing the High Standard Air Cooling EPS Automatic Block Molding Machine by Zhongji – the solution that is perfect your molding needs.

This fully automatic device incorporates more impressive range technology to produce the standard in highest EPS blocks. Every time using its state-of-the-art air coolant system, it guarantees constant molding results. This particular feature additionally helps reduce the general period time, allowing for more efficient production.

The High Standard Air Cooling EPS Automatic Block Molding Machine by Zhongji boasts an incredibly user-friendly interface with programmable touchscreen display settings and heat control is automated. Its security features make sure a secure and operation which is seamless offering you satisfaction during use.

This block molding machine is highly versatile, with the capacity of creating obstructs of varying sizes and thicknesses. Its adjustable vapor pressure and filling height, further enhance its freedom and permit it to pay attention to diverse needs.

This high-performance machine was built to optimize power usage while delivering output capability. Its energy-efficient features include heat insulation plus a stress which has automated system, which decreases temperature loss and decreases power consumption.

The High Standard Air Cooling EPS Automatic Block Molding Machine additionally solidifies Zhongji’s track record of making revolutionary and machine of high-quality. Its components are constructed of durable, high-quality materials, ensuring longevity and efficiency.

The Zhongji High Standard Air Cooling EPS Automatic Block Molding Machine can also be extremely sustainable as well as its impeccable performance capabilities. It is often created using environment-friendly elements that provide a low impact is environmental.

With the use of PLC Controller (Programmable Logic Controller) and "Touch Screen, the automatic looping process of opening and closing of the molds, feeding, heating, heat preservation, cooling, mold ejection, and releasing the final product.

Main Features

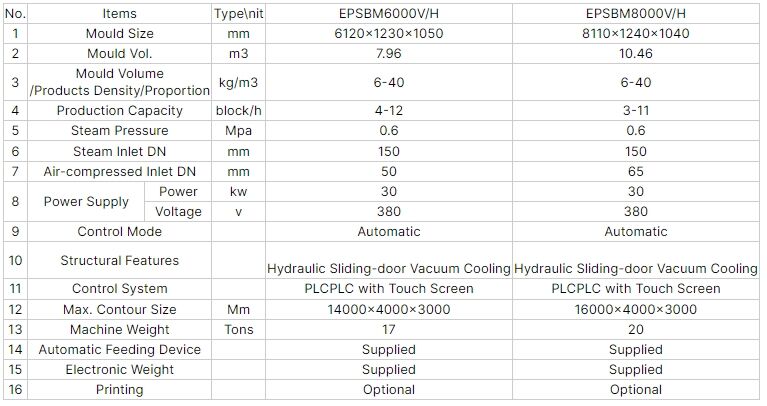

1.The D type EPS Block Forming Machine has a specially designed Double Gas Chambers (National Patent), based on the previous Single Gas Chamber EPS Block Forming Machine, which saves up to 30% energy, fast EPS Block forming speed, with good bonding property, uniform density. This solves the problem of uneven density of the upper and lower feeding inside the mold cavity of the Single Gas Chamber EPS Block Forming Machine, when the EPS Block edges are not fully filled with the EPS material, and the drawbacks of moisture inside the EPS Block.

2. The machine is assembled by using high quality copper welding method, and goes through aging treatment. Which gives the machine high strength, without deformation. This machine can produce EPS Block products with density of 6~40kg/m3.

3. The machine can optionally be equipped with the Touch Screen, Automatic Conveyer and Automatic Electronic Weighing Scale, Printer.

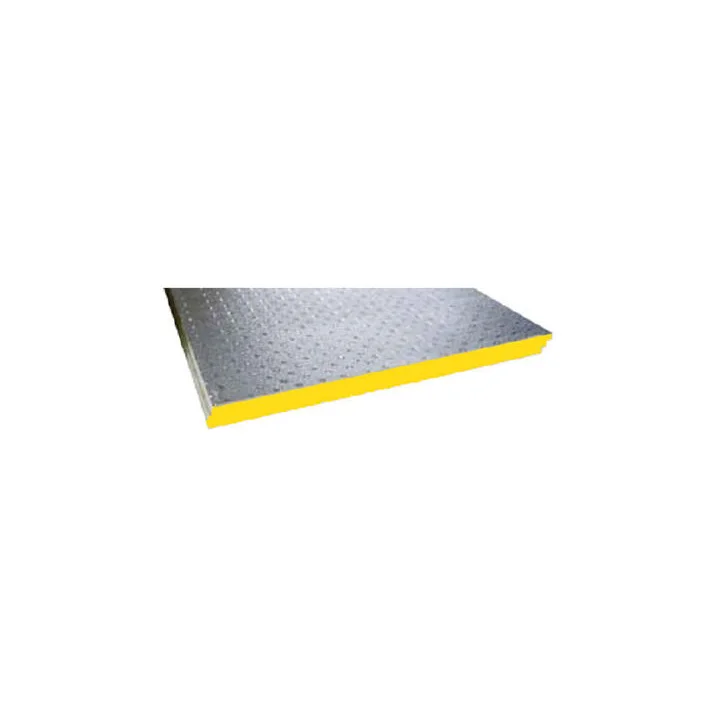

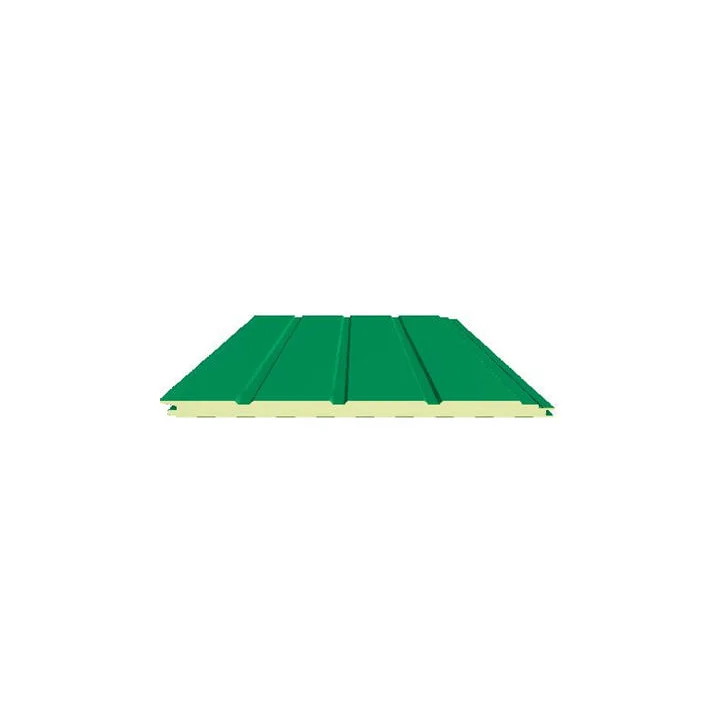

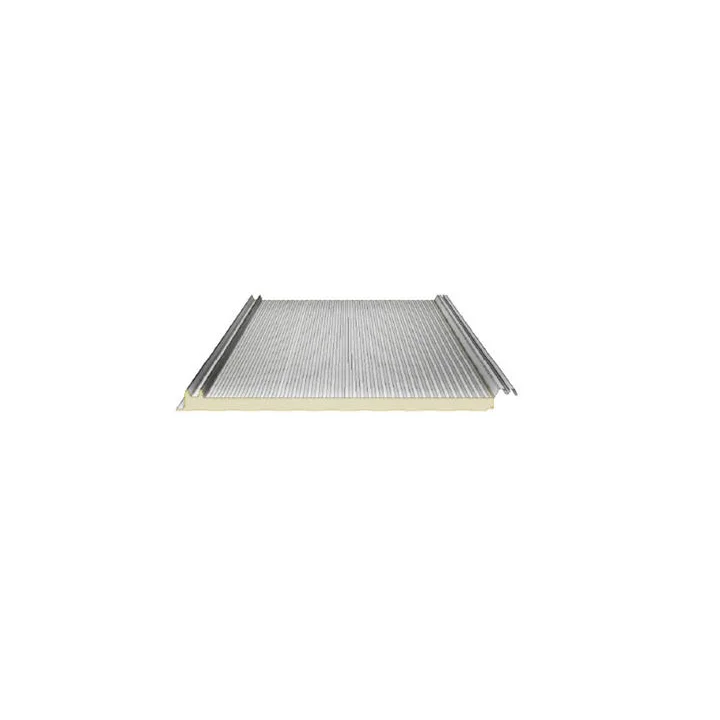

4. This machine can be used together with lhe Color Steel Sandwich Panel Production Line to produce the width of 850mm, 950mm and 1150mm EPS Blocks, and can also produce the width of 1000mm EPS Block for building construction purposes.

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2. The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our Company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance cannot be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ