- Overview

- Inquiry

- Related Products

1. The automation phase of the beads expansion is accomplished by loading the EPS beads into the feeder, expansion of the EPS beads, the expanded EPS beads will then enter the fluidized bed (optional), and then go through the Centrifugal Fan and Conveying device to be transported into the Aging Silos;

2. The machine's feeder system includes the first-phase and second-phase feeders. The first-phase feeder uses the transformer to regulate the feeding speed, the second-phase feeder uses the method of movement rail and wind pipe to blow the EPS Beads to cool down the temperature, ensuring that feeding is stable;

3. To accomplish the automatic feeding, the Photoelectric Switch should control the level of the EPS beads in the Automatic Negative Pressure Feeder (Optional).

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

Brand: zhongji

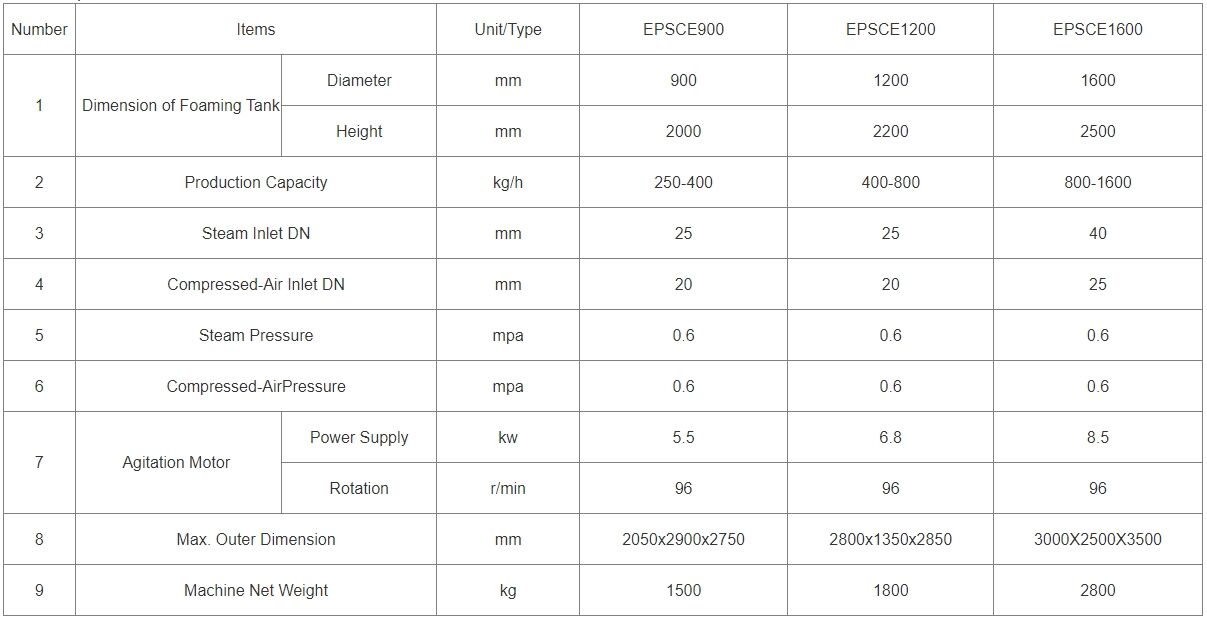

Introducing the High-performance EPS Continuous Pre-Expander from Zhongji! This top-of-the-line product is perfect for businesses looking to streamline their EPS foam production process.

The pre-expander is a component is vital the EPS foam production process, accountable for expanding the raw EPS beads to the lightweight foam material most of us know and love. The Zhongji pre-expander produces high-quality foam with ease and efficiency with its superior designs and cutting-edge technology.

One of the key features of the High-performance EPS Continuous Pre-Expander is its continuous operations. This machine runs continuously, maximizing manufacturing output unlike old-fashioned batch pre-expanders that need regular stops and starts. This means less downtime and more foam produced in the same amount of time – a advantage is huge any foam production facility.

Boasts an processing is impressive, capable of pre-expanding up to four a lot of EPS beads per hour. It is a increase is significant processing speed compared to other pre-expanders available on the market, allowing companies to produce more foam in less time.

Incredibly user-friendly and easy to regulate along with its high production capability. The device comes with a feeling screen program, permitting operators to regulate the settings and monitor production production with simplicity.

Energy-saving. The machine was created to use less power during the process is pre-expansion resulting in lower working costs. This is particularly essential for companies looking to reduce their carbon operating and footprint expenses simultaneously.

This pre-expander is an investment you won't regret. With its advanced features, superior design, and energy-saving technology, you can't go wrong with Zhongji.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ