- Overview

- Inquiry

- Related Products

zhongji

High-performance EPS Automatic Vertical Block Molding Machine is the perfect solution for those who seek increased efficiency and automation in their production processes. This state-of-the-art machine boasts advanced technology and precision engineering that ensure a high-quality and consistent output every time.

The vertical design optimizes the employment of space in factories, because it calls for less living area compared to block is horizontal machines. It is also effective at producing blocks of various sizes, making it highly adaptable and versatile to your requirements of different industries.

Speeds up manufacturing cycles, allowing businesses to meet up with need requirements on time and at a lower general cost with an output capacity all the way to 30 obstructs per hour. It also features intuitive touch-screen controls that make it possible for operators to set the parameters for the molding process, ensuring consistency and accuracy.

Reduces labor is manual it features a machine-controlled procedure for feeding the raw materials to the molding machine. The process is highly efficient, making sure waste is minimized, and also the output is consistent throughout the production process.

Made with top-quality materials, ensuring durability and performance throughout its life cycle. This reduces maintenance expenses and maximizes uptime for the user.

Safety is a priority that top this machine as well. It is designed with multiple safety features that ensure procedure is safe. Included in these are safety fences, emergency stop switches, and protection is overload among other people.

The machine's energy efficiency is also commendable. Offers an insulation is advanced that reduces energy consumption during the production process, rendering it a more green option when compared with traditional block molding methods.

Get your EPS Automatic Vertical Block Molding Machine today and experience the Zhongji difference.

EPS automatic vertical machine adopts hydraulic system and PLC control program; and put the foamed and matured EPS beads into the mold cavity, and the steam heating system is used to make the steam directly enter the mold cavity.

Main Features

1 .With the use of PLC Controller (Programmable Logic Controller) and Touch Screen, the automatic looping process of opening and closing of the molds, feeding, heating, heat preservation, cooling, mold ejection, and releasing the final product from the machine will be accomplished.

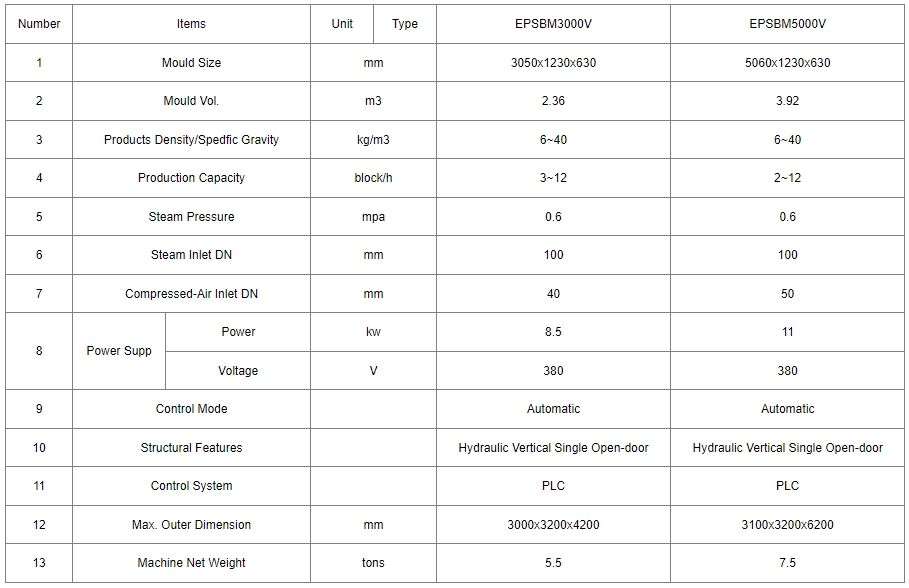

2. This machine can produce EPS Block products with density of 6~40kg/m3, as well as fast EPS Block forming speed, uniform bonding, low moisture content, with very minor deformation.

3. The Pre-Expander Beads are fed in from the top of the machine, this will save energy, fast feeding speed, uniform density, especially suitable for light-weight EPS Block production.

4. The machine has a compact structure that occupies a very small space.

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2. The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our Company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance cannot be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ