- Overview

- Inquiry

- Related Products

zhongji

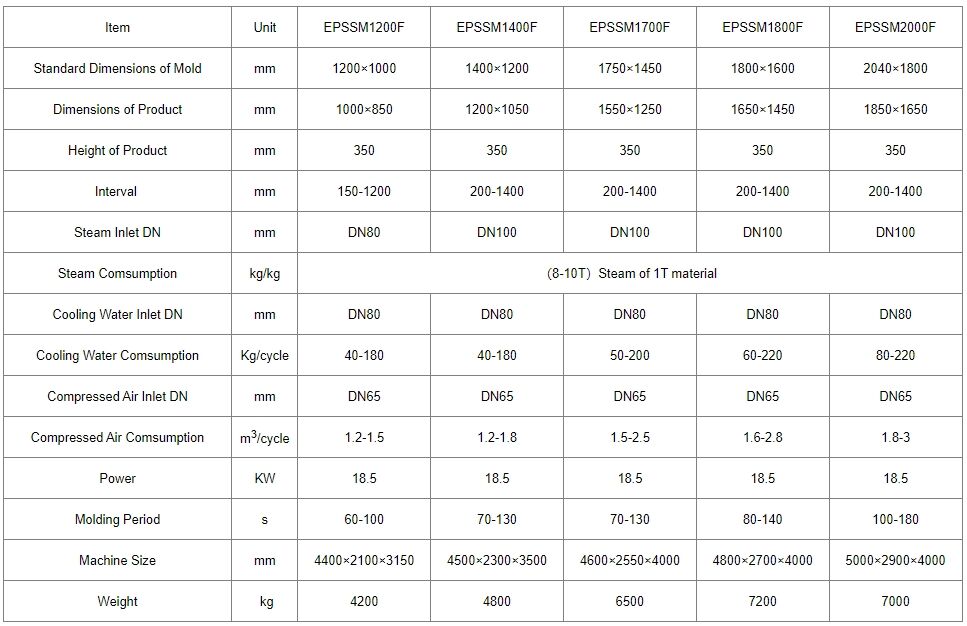

Introducing the Factory Direct Supply Mold that is quickly changing Shape Machine - Zhongji's offering is latest and innovative within the production industry. This machine is in advanced cutting-edge technology, built to offer efficient and outcomes which can be prompt production is maximizing.

This molding unit is wonderful for companies attempting to improve their manufacturing capability, streamline their manufacturing process, and bring services to promote faster. Kit can cause product which is various and shapes with convenience, saving businesses some time resources in switching molds along with its form is fast-changing ability.

The machine's robust construction features sturdy materials who promise long-term performance, enabling it to manage absolutely the production is most that demanding. Also, the apparatus's compact program and design is operation this user-friendly, even for newbies.

Another standout function from the molding device is its energy-efficient attributes, reducing energy consumption and expenses without compromising on performance. This implies savings that might be companies which can be significant reduces their carbon impact into the work.

Moreover, factory-direct supply really helps to make sure purchasers will get the worth much better because of the investment, having an obvious kind of interaction making use of the manufacturer. This also eliminates markups that are unneeded decreases times are lead benefiting organizations who give attention to tight schedules.

The Zhongji brand is actually through the forefront of manufacturing solutions for longer than a decade, and also this molding device is not any exclusion with regards to their dedication to quality and innovation. Their dedication to quality is obvious to the feedback is reviews are countless positive happy consumers who possess utilized their products or services.

The Factory Direct Supply quickly changing Mold Shape Molding Machine by Zhongji is surely an asset that is indispensable more or less any manufacturing business wanting to simply take their production abilities to your level is various. Along with cutting-edge technology, sturdy construction, energy-efficient attributes, and user-friendly interface, organizations can optimize their effectiveness, conserve costs, while increasing profits. Along with the Zhongji brand backing it, purchasers can sleep effortless, understanding that a fantastic happens to be received by them item which is a game-changer within their manufacturing operations.

This fast changing mold EPS shape molding machine is not only has advantage of short changing time(only takes 10 to 20 minutes), but also is energy saving and high efficiency.

1. All templates are welded by 25/40mm high-quality Q235 steel plates, and the deformation of the templates is avoided by heat treatment and increased the strength of the equipment;

2. The structure of this machine adopts European structure, which has the function of quick mold change;

3. This quick mold change machine with steam chamber mounted on machine already,which saves the mold cost for customers. Moreover, the equipment comes with a mold quick installation trolley. When installing the mold, the customer can put the ejectors and the filling guns on the mold first, and then remove the original mold and install the new mold. The whole process only takes 15-20 minutes.

4. There is a beautiful aluminum frame on the periphery as a guardrail, and safety doors on the left and right and behind, and switches on the safety doors. As long as people enter, the machine will stop immediately, and the machine will alarm at the same time. After the machine door is closed, the machine continues to work.

Feeding system:

1. With vertical double barre; with three feeding modes: normal pressure, high pressure and vacuum, equipped with automatic material level detection and automatic replenishment of raw materials; the double barrels use disc rotating discharge; has many discharge holes. .

2. Double barrel structure, with a single barrel to feed separately, can produce products of different densities, and can realize multi-density production.

Steam system:

1. The steam pipe adopts a large diameter for air intake, and the heating speed is fast. The built-in steam dispersion structure makes the steam evenly enter the mold chamber to heat the product.

2. With PID proportional valve control,pressure gauge monitoring, and electric proportional valve controls the steam inlet pressure through chamber pressure feedback, so that the heating accuracy is high and the steam loss is reduced by 30%.

Cooling system:

1. The high-performance vacuum system and the unique spray vacuum system make the steam during cooling fully melt into the water, which greatly improves the suction efficiency of the vacuum pump, makes the vacuum negative pressure quickly form in the mold cavity, and reduced the cooling time.

Hydraulic system:

1. The hydraulic system adopts the imported Autos brand solenoid valve from Italy. The pressure control system automatically feedbacks the clamping pressure and the unlocking pressure and unlocking state, which makes the machine system stable and reliable. The system has the function of automatic switching between high, low and medium pressure, which greatly saves energy consumption.

Mold change system:

1. Changed the traditional platen fixing mold. The hydraulic one-key mold clamping and mold opening device can quickly change the mold and reduce the mold change time.

2. The mold and the trolley are fixed together in the mold installation area, and the mold is pushed into the molding machine by rail to realize quick mold change, reduce downtime and improve equipment usage time.

Electrical System:

1. The machine is controlled by PLC and touch screen, and all processes such as mold clamping - feeding - heating - heat

preservation - cooling - demolding - mold opening are fully automatic.

2. The electrical components are all world-renowned brands, such as Siemens, Mitsubishi, Schneider, Omron, etc., to improve the stability of the equipment.

3. All pressure feedbacks use pressure sensors, which can control the steam pressure more accurately, make the machine more energy-saving, and at the same time improve the efficiency of the machine.

4. The quick-change molding machine adopts the top configuration. The computer adopts the world famous brand PLC and the world famous brand touch screen; the hydraulic system adopts the world famous brand hydraulic components; the valve adopts the German GEM valve; the control solenoid valve adopts the world famous brand integrated control bus; the steam and compressed air pressure and temperature control, which makes the machine run smoothly.

5. Controlled by PLC, the equipment parameters are easy to operate and easy to adjust.

Type A equipment is economical type, using domestic high-quality brand components, valves, motors, pipes, etc.

Type B equipment is high-quality type, using world-renowned brand components, valves, motors, pipes, etc.

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2. The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our Company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance cannot be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ