- Overview

- Inquiry

- Related Products

zhongji

If you're trying to find a durable and dependable EPS cleaner is automatic molding machine, take a look at Zhongji's types of commercial equipment. The unit will definitely rise above your objectives whether you will have to create foam obstructs when it comes to customers or simply want a dependable machine for the factory.

Manufactured from top-notch materials, Zhongji's EPS vacuum cleaner which can be automatic are made to provide several years of dependable performance under perhaps the most demanding conditions. These devices function advanced technologies that ensure uniform cooling and heating through the foam blocks, resulting in consistently things that come in high-quality time.

With their durability, Zhongji EPS vacuum molding and it is automatic may also be very versatile. They often have a variety is wide of options, allowing you to adjust the dimensions, shape, and thickness of your foam blocks as required. These machines are designed for the whole thing whether you are creating large blocks for construction projects or little, intricately-shaped pieces for packaging.

Maybe first and foremost, Zhongji's EPS vacuum molding and it is automated are incredibly user-friendly. The unit are actually an easy task to run, also for anyone with little to no to no expertise in commercial manufacturing with intuitive controls and user-friendly software. This can cause them to become a selection that will be ideal small enterprises or anybody attempting to expand their production capabilities.

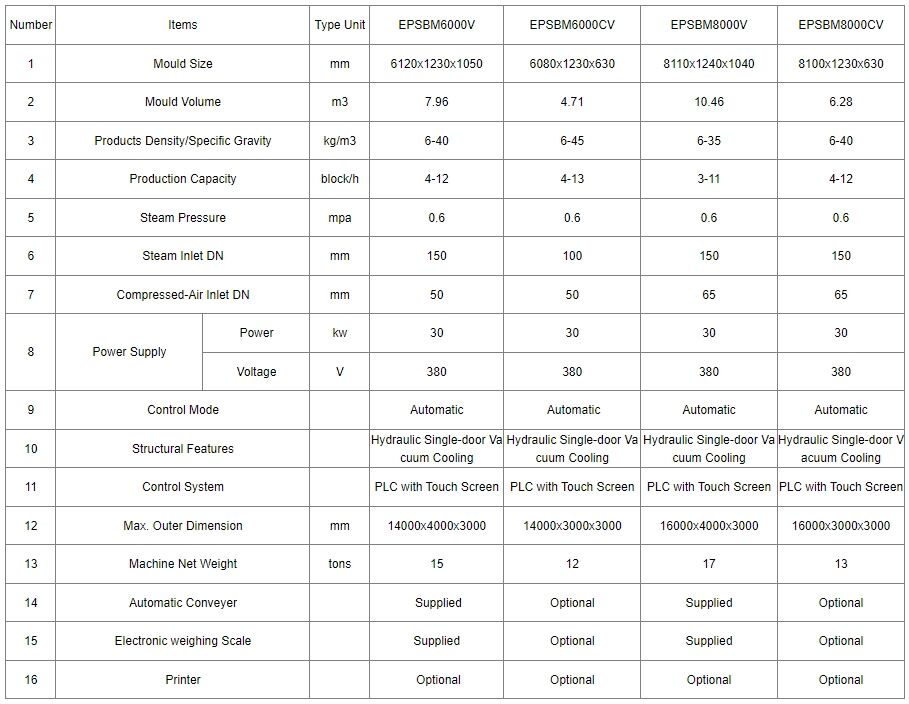

EPS automatic vacuum block molding machine adopts PLC programmable industrial controller and computer touch screen to complete the automatic cycle process of opening and closing the machine, feeding, heating, heat preservation, cooling, demoulding.

Main Features

1. With the use of PLC Controller (Programmable Logic Controller) and Touch Screen, the automatic looping process of opening and closing of the moulds, feeding, heating, heat preservation, cooling, mould ejection, and releasing the final product from the machine will be accomplished.

2. The Automatic Vacuum Control System does the feeding, heating and cooling.3. The Vacuum System consists of the Vacuum Storage Tank, Vacuum cooling Tank, and highly efficient water-recycling vacuum pump.

4. The machine is coupled by using high quality welding method, and goes through aging treatment, which gives the machine high strength, and without deformation. The density of the EPS Block can reach 6~40kg/m3, with fast EPS Block forming speed, uniform bonding, low moisture content, and with very minor deformation.

5. Applying a special Teflon coating to the surface of the mould cavity (Optional) makes the EPS Block to be easily ejected or released out of the mould.

6. The thickened wall Vacuum EPS Block Forming Machine has Automatic Conveyer, Automatic Electronic Weighing Scale, and the Automatic Printer.

7. This machine can be used to produce the width of 850mm, 950mm and 1150mm EPS Blocks, and also produce the width of 1000mm EPS Block for buildings.

1.The company workshop 40,000 square meters, has introduced the first-class multi-station machining center, CNC lathes, CNC milling machines and other high-precision processing equipment. Such as the value of 4.5 million yuan 3mx8m gantry machining center, and the value of 300 million yuan 2.5 mx12m gantry milling machine.

2. The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our Company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance cannot be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ