Foaming Your Way to Comfort and Safety

Introduction:

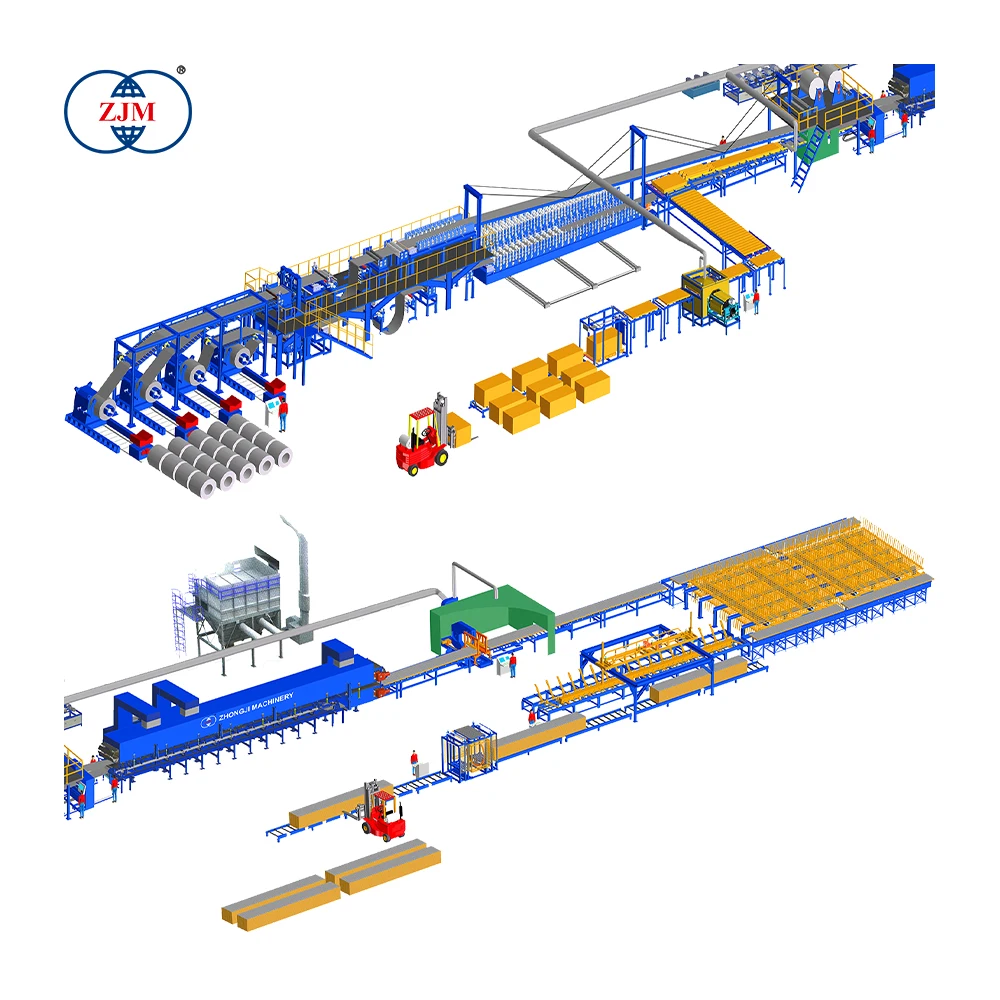

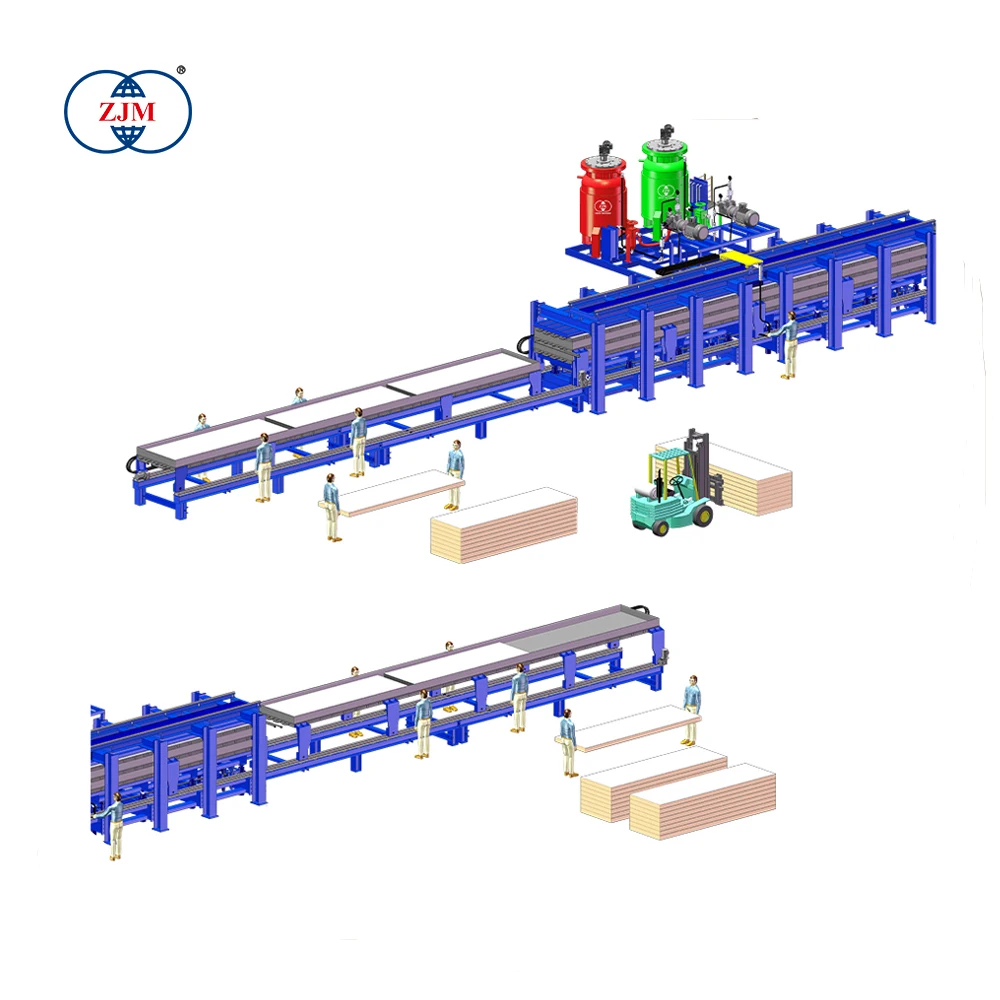

Foam production delivers a versatile answer modern-day challenges in insulation, transportation, and packaging. The unique properties enable it to deliver cushioning, weather resistance, and thermal insulation among other benefits. However, to understand the full potential of foam it's important to use state-of-the-art production processes and machinery. The zhongji foam block machine is an automated production system that really helps you to create high-quality, customized foam products with minimal human intervention. We look into the advantages, innovations, safety protocols, and potential applications of the foam production line.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ