- Tổng quan

- Truy vấn

- Sản phẩm liên quan

Zhongji

Giới thiệu Máy ép định hình EPS/EPP công nghệ Ý bền lâu, một sản phẩm hàng đầu từ thương hiệu đáng tin cậy, Zhongji. Máy chất lượng cao này có cấu trúc bền bỉ và công nghệ Ý, làm cho nó trở thành một giải pháp đáng tin cậy và kéo dài thời gian sử dụng cho nhu cầu tạo hình của bạn.

Sử dụng công nghệ EPS/EPP mới nhất, Máy ép định hình Zhongji đảm bảo độ chính xác trong mỗi lần sử dụng. Máy này có thể đáp ứng nhu cầu sản xuất của bạn dù bạn muốn sản xuất các sản phẩm đóng gói, vật liệu cách nhiệt hoặc thậm chí là đồ trang trí.

Được thiết kế với những vật liệu bền vững, Máy ép định hình Zhongji được chế tạo để chịu đựng được sự khắc nghiệt của việc sử dụng thương mại. Cấu trúc này rất bền nên máy sẽ vận hành trơn tru trong nhiều năm tới, giảm thiểu nhu cầu sửa chữa hoặc thay thế đắt tiền.

Điểm nổi bật ấn tượng của máy này là công nghệ Ý. Ý nổi tiếng với các quy trình sản xuất đổi mới, và máy ép định hình này không phải là ngoại lệ. Máy có thể sản xuất ra những hình dạng chất lượng cao đáp ứng đúng yêu cầu của sản phẩm với kỹ thuật chính xác từ Ý.

Máy ép định hình Zhongji cung cấp sự dễ dàng sử dụng vô song cùng với kết cấu bền bỉ và công nghệ hàng đầu. Chương trình có thiết kế thân thiện với người dùng giúp việc tạo ra các hình dạng mong muốn một cách nhanh chóng và hiệu quả trở nên đơn giản cho người vận hành. Máy này có thể là sự bổ sung hoàn hảo cho bất kỳ hoạt động sản xuất nào nhờ vào các cài đặt đơn giản và bảo trì dễ dàng.

Nếu bạn muốn đưa hoạt động sản xuất của mình lên một tầm cao mới, hãy cân nhắc đầu tư vào Máy ép định hình Zhongji ngay hôm nay.

Máy ép định hình EPS/EPP công nghệ Ý sử dụng công nghệ chín chắn độc đáo của Ý và trang bị phụ kiện điện tử của các thương hiệu nổi tiếng thế giới.

Tính năng chính

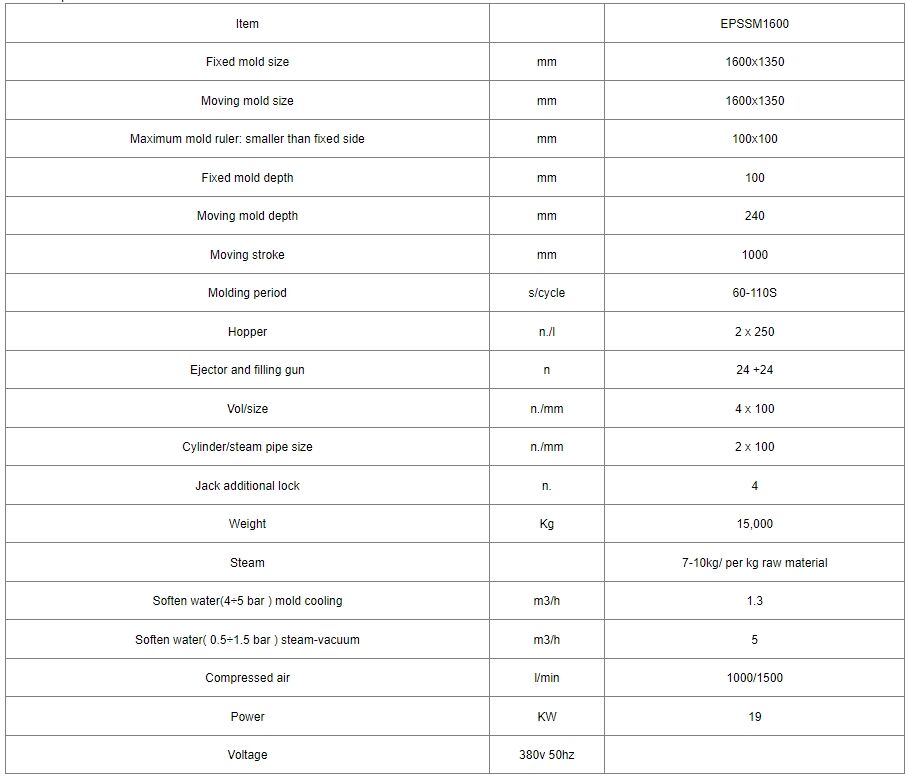

1. Cấu trúc máy: Cấu trúc thiết bị được làm từ thép, hàn điện, phun cát và sơn epoxy.

2. Phòng khí khuôn và phần đỡ được hàn từ thép đã qua xử lý thông thường và chống ăn mòn.3. Hướng dẫn của khuôn động có bốn thanh chống, bushing hướng dẫn với chức năng tự bôi trơn và được điều khiển bởi hai xi lanh thủy lực.

4. Sự di chuyển của buồng khuôn động được kiểm soát bởi một bộ mã hóa với độ chính xác 2/10mm, điều này kiểm soát việc trở về không tự động mỗi lần và làm nóng trước tự động.

5. Thiết bị thay đổi khuôn nhanh: khuôn được lắp ráp trong quá trình sản xuất của thiết bị, với tất cả các phụ kiện và đầu nối cần thiết cùng với các bộ phận hỗ trợ khuôn bổ sung, thiết bị chỉ dừng lại trong vài phút để hoàn thành: khóa của bộ phận hỗ trợ khuôn, kết nối, hai đầu nối nhanh, một đầu nối để đổ nước nhanh, đầu nối nhanh cho silo và đầu đẩy.

6. Máy chủ yếu bao gồm các phần sau: PLC công nghiệp với phần mềm để điều khiển sản xuất, hệ thống thay mold nhanh chóng, đơn vị động lực thủy lực, tải áp suất, cần cẩu, cài đặt áp suất bằng điều khiển tỷ lệ với PC giữa hai buồng hơi, chuyển động bằng encoder cho phép kiểm soát vị trí trong quản lý tự động hoàn toàn qua chu kỳ sản xuất, cung cấp các menu đã được xác định và thử nghiệm bởi người vận hành, đồng thời cung cấp một loạt các chuỗi và sự kết hợp đa dạng để dễ dàng sửa đổi và sử dụng, một loạt tài liệu kỹ thuật hướng dẫn: sử dụng và bảo trì, thiết bị, tài liệu về việc nạp vật liệu vào silo, thông số kích thước mold, quy trình giám sát thủ công.

1. Xưởng của công ty có diện tích 40.000 mét vuông, đã đưa vào sử dụng trung tâm gia công đa trạm hạng nhất, máy tiện CNC, máy phay CNC và các thiết bị gia công độ chính xác cao khác. Chẳng hạn như trung tâm gia công dạng cổng cỡ 3mx8m trị giá 4,5 triệu nhân dân tệ, và máy phay dạng cổng cỡ 2,5mx12m trị giá 300 triệu nhân dân tệ.

2. Công ty có một đội ngũ kỹ thuật viên chuyên nghiệp, cung cấp dịch vụ sau bán hàng không gián đoạn 24 giờ.

(1) Lắp đặt và điều chỉnh

Thiết bị đã đến xưởng của khách hàng, theo bản vẽ bố trí phẳng của thiết bị của chúng tôi. Chúng tôi sẽ cử kỹ thuật viên có kinh nghiệm để lắp đặt, điều chỉnh và thử sản xuất thiết bị, và đảm bảo thiết bị đạt công suất sản xuất định mức của dây chuyền.

(2) Đào tạo

Công ty của chúng tôi cung cấp đào tạo kỹ thuật cho khách hàng của mình. Đào tạo bao gồm cấu trúc và bảo trì thiết bị, kiểm soát và vận hành thiết bị, các kỹ thuật viên có kinh nghiệm sẽ hướng dẫn và xây dựng chương trình đào tạo. Sau khi đào tạo, nhân viên kỹ thuật của bên mua có thể nắm vững việc vận hành và bảo trì thiết bị, có thể điều chỉnh quy trình và xử lý các sự cố khác nhau.

3. Vấn đề chất lượng sau bán hàng sẽ được trả lời trong vòng 2 giờ, nếu hướng dẫn qua điện thoại hoặc video không giải quyết được, sẽ cử kỹ sư đến hiện trường trong vòng 24 giờ đối với thị trường trong nước để giải quyết vấn đề.

4. Giá bán trực tiếp từ nhà máy với chiết khấu, nhà máy rộng 40.000 mét vuông, doanh nghiệp xuất khẩu 20 năm, chứng nhận CE, hơn 100 bằng sáng chế.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ