- Genel Bakış

- Sorgu

- İlgili Ürünler

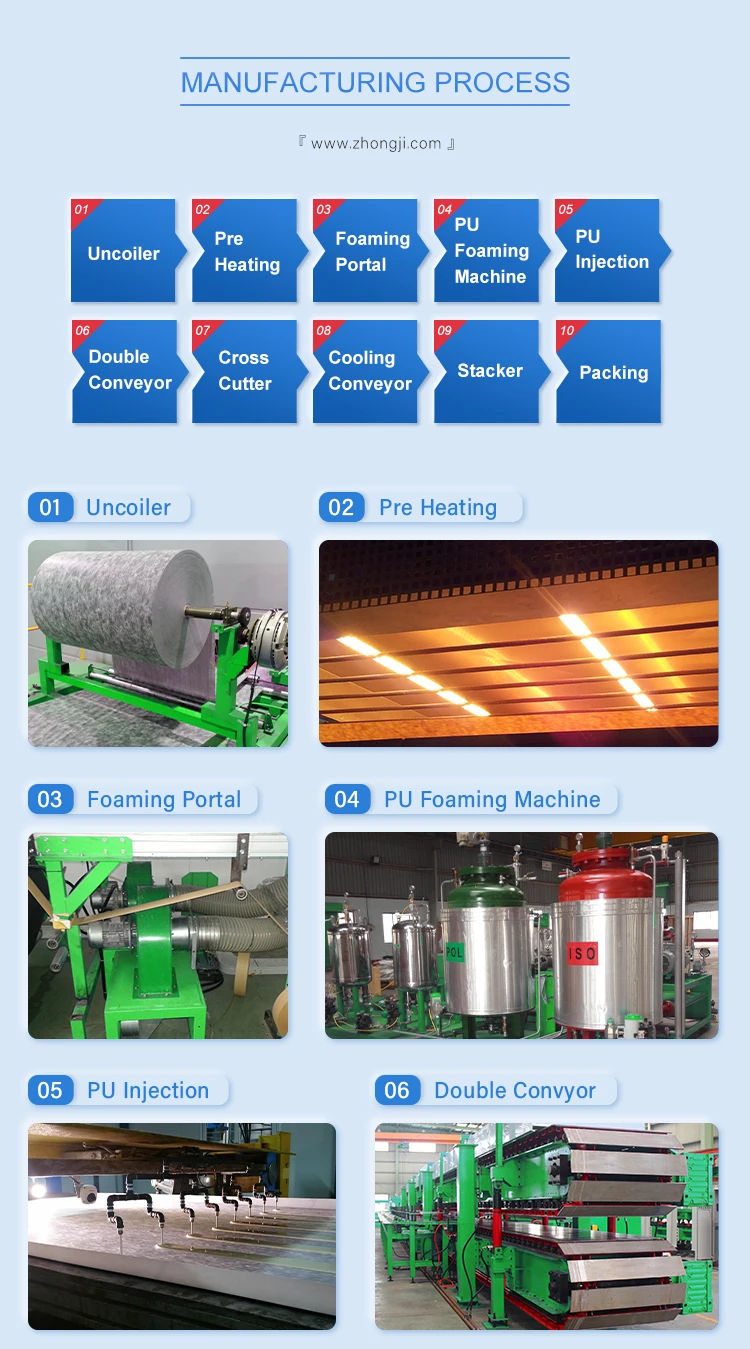

Ürün Detayları

1. Malzeme tankı:

1) 2 adet 1000L malzeme tankı ile donatılmıştır, iç kaplama çelik ceketli tipte olup, karıştırma motorunun gücü

11KW'dir, bu da reçine malzemesinin ön karışımını yapmak için kullanılır.

2) 300L malzeme tankı ile donatılmıştır, iç kaplama çelik ceketli tiptedir, sertleşme ajanı için kullanılır.

2. Pompa seti:

1) Bir metraj pompa: dişli pompa, aşamalı olmayan hız düzenlemesi, güç 5.5KW, patlama riski olan motor.

2) Bir sertleştirici metraj pumması, hidrolik membran metraj pumması ile donatılmış, güç 0.37KW, patlama riski olan motor.

3) Bir siklopendan besleme pumması: hidrolik membran metraj pumması ile donatılmış, güç 0.37KW, patlama riski olan motor.

4) Bir fenol reçini besleme pumması: rotor pompa ile donatılmış, güç 3KW, patlama riski olan motor.

3. Karıştırma başı seti:

1) 4500rpm/dakika karıştırma hızına sahip bir mekanik karıştırma başı seti, güç 2.2KW patlama riski olan motor.

2) Otomatik temizleme cihazıyla donatılmış (25L temizleme tankı dahil, çelikten yapılmış).

4. Ham madde sıcaklık kontrol sistemi:

5-HP soğutucu ve uygun su-sıvı elektrik vanası ile donatılmış, malzeme sıcaklığı gerçek zamanlı olarak gösterilir ve ayarlanabilir, ısıtıcı su tankı bulunur ve gücü 6KW'dır. Sistem ham madde sıcaklığının otomatik kontrolünü sağlar.

5. Yanıcı gaz izleme sistemi:

Pozlama sistemindeki yanıcı gaz algılanır, 6 adet yanıcı gaz kontrol ve ölçme aletiyle donatılmıştır, otomatik olarak alarm verir ve aynı anda duman sistemini aktive eder, böylece yanıcı ve patlayıcı gazı zamanında etkili bir şekilde atar.

2 adet fan, 6 tane yanıcı gaz dedektörü ve bir monitör setiyle donatılmıştır, buna karşılık gelen ventileasyon boruları vardır.

Fan gücü 4KW 20000m3/saat rüzgar basıncı 0.3MPa.

6. Elektrikli kontrol kabini:

Pozlama makinesi PLC kontrolü kullanır ve döküm kalibrasyon zamanı, temizleme zamanı, üfleme zamanı ve eylem programı önceden ayarlanabilir.

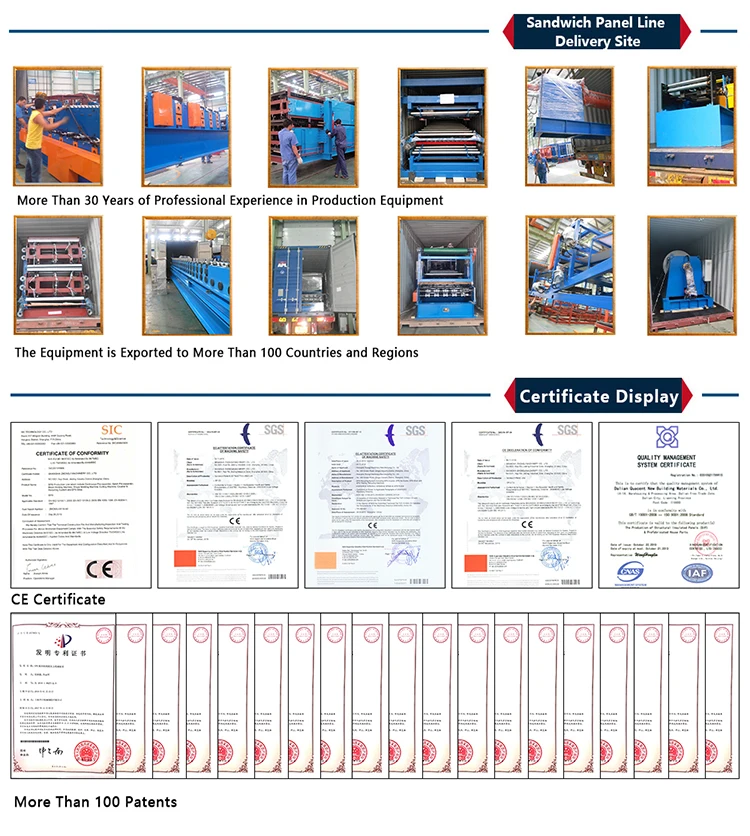

Şirket ve Hizmet Avantajları:

2. Şirkette profesyonel Ayar Uzmanı ekibi bulunmakta, 24 saatlik kesintisiz satış sonrası hizmeti sunmaktadır.

(1) Kurulum ve ayarlama

Ekipman müşteri atölyesine ulaştığında, ekipmanımızın düzleme düzenine göre deneyimli teknisyenlerimizi kurulum, ayarlama ve deneme üretim için gönderiyoruz ve ekipmanın planlanan üretim kapasitesine ulaşmasını sağlıyoruz.

- Çizgi.

(2) Eğitim

Şirketimiz müşterilerimize teknik eğitim sağlar. Eğitim, ekipmanın yapısı ve bakımı, kontrolü ve işletilmesi konularını içerir; deneyimli mühendisler rehberlik eder ve eğitim programını oluşturur. Eğitimden sonra, alıcı teknik personeli ekipmanın işletilmesini ve bakımını öğrenebilir, süreçleri ayarlayabilir ve farklı hataları ele alabilir.

3. Satış sonrası kalite sorunlarına 2 saat içinde yanıt verilir, eğer telefon veya video kılavuzuyla çözülemezse, yurt içi için 24 saat içinde mühendis gönderilir ve sorun yerinde çözülür.

4. Fabrika doğrudan satış fiyatı indirimleri, 40.000 metrekare fabrika, 20 yıllık Dış Ticaret Şirketi, CE sertifikası, 100'den fazla patent.

|

Ürünler

|

TUR/ BirIM

|

SP-PU-C

|

|

Hat Boyutları (U × E × H)

|

mm

|

20000 × 50000 × 7000

|

|

Toplam güç

|

W

|

70000

|

|

Üretim Hattının Net Ağırlığı

|

kg

|

70000

|

|

Üretim Hattı Hızı

|

m/dak

|

0-4,5

|

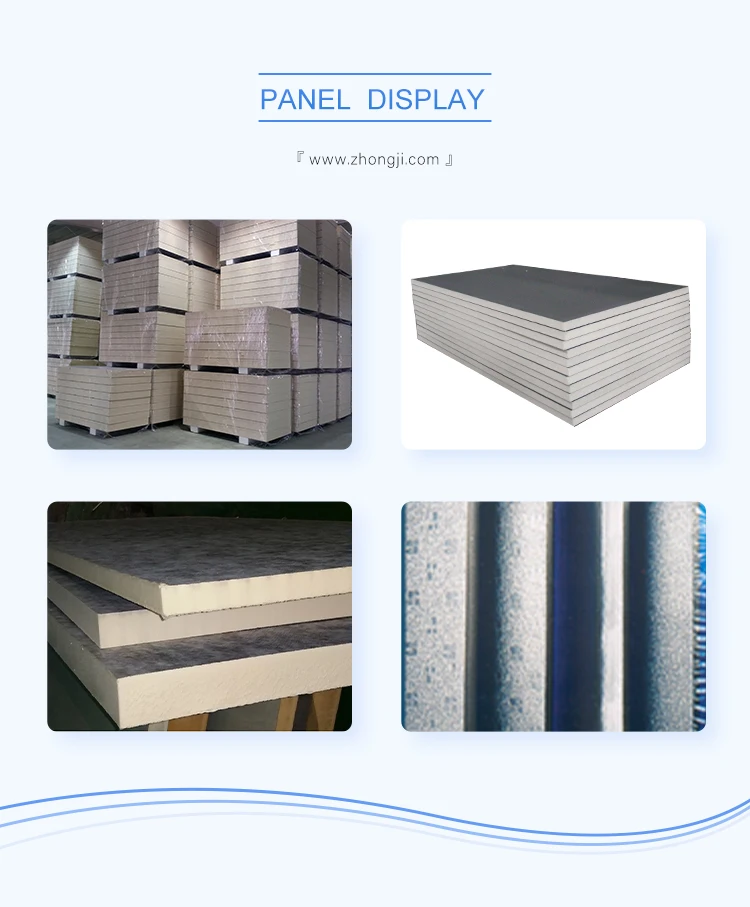

2. L-tipi, Düz tipi ve sürekli panel için başlar olmak üzere üç tür PU sandviç panel üretim hattı sunuyoruz. Tüm PU sandviç panel üretim hatları, 2 ila 6 bileşen arasında çoklu bileşenli olarak kullanılabilir.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ