- ภาพรวม

- สอบถาม

- ผลิตภัณฑ์ที่เกี่ยวข้อง

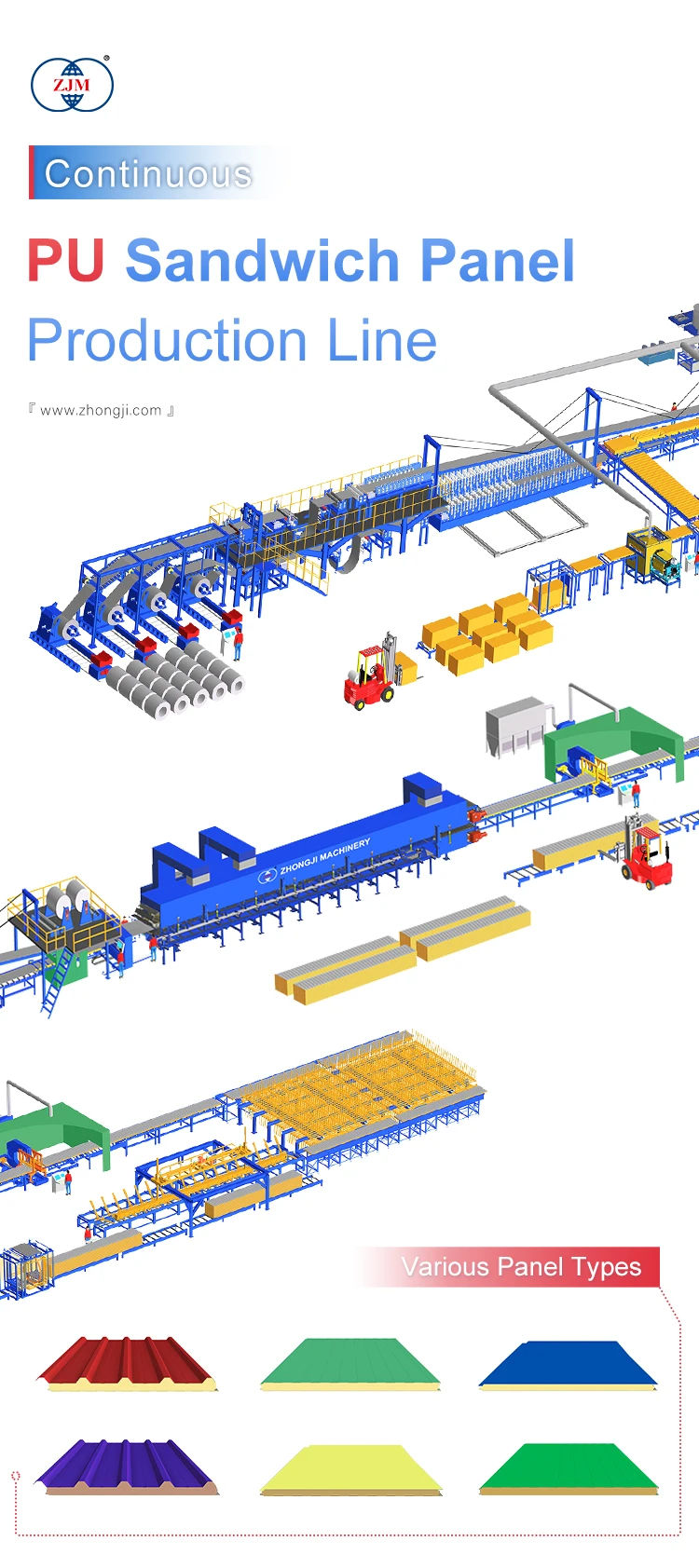

รายละเอียดสินค้า

ข้อได้เปรียบของบริษัทและการให้บริการ:

2.บริษัทมีทีมงานผู้ตรวจสอบมืออาชีพ พร้อมให้บริการหลังการขายตลอด 24 ชั่วโมงโดยไม่มีข้อตัดตอน

(1) การติดตั้งและการปรับแต่ง

อุปกรณ์มาถึงโรงงานของลูกค้า โดยจะตามแบบแปลนที่เราวางไว้ เราจะจัดเตรียมช่างเทคนิคที่มีประสบการณ์ในการติดตั้ง อุปกรณ์ ทดสอบ และผลิตเพื่อให้อุปกรณ์สามารถทำงานได้ตามกำลังการผลิตที่กำหนด

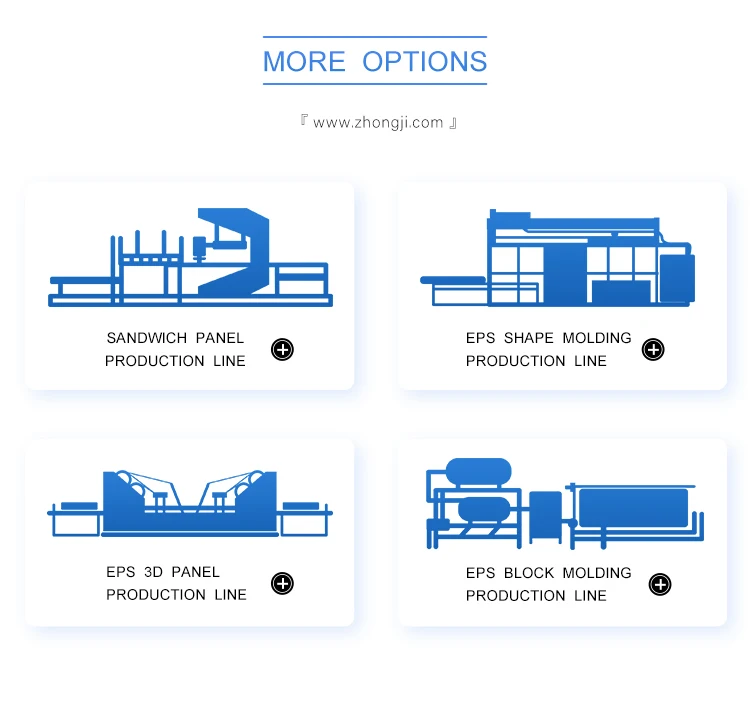

สายการผลิต

(2) การฝึกอบรม

บริษัทของเราให้การฝึกอบรมทางเทคนิคแก่ลูกค้า การฝึกอบรมครอบคลุมถึงโครงสร้างและการบำรุงรักษาของอุปกรณ์ การควบคุมและการใช้งานอุปกรณ์ ช่างเทคนิคที่มีประสบการณ์จะเป็นผู้แนะนำและจัดทำโปรแกรมการฝึกอบรม เมื่อเสร็จสิ้นการฝึกอบรม บุคลากรทางเทคนิคของผู้ซื้อจะสามารถควบคุมและบำรุงรักษาระบบอุปกรณ์ รวมถึงปรับกระบวนการและจัดการกับความล้มเหลวต่างๆ ได้

3.ปัญหาด้านคุณภาพหลังการขาย จะตอบกลับภายใน 2 ชั่วโมง หากการแก้ไขผ่านทางโทรศัพท์หรือวิดีโอไม่สามารถแก้ไขได้ จะส่งวิศวกรภายใน 24 ชั่วโมงในประเทศเพื่อแก้ไขปัญหาที่สถานที่

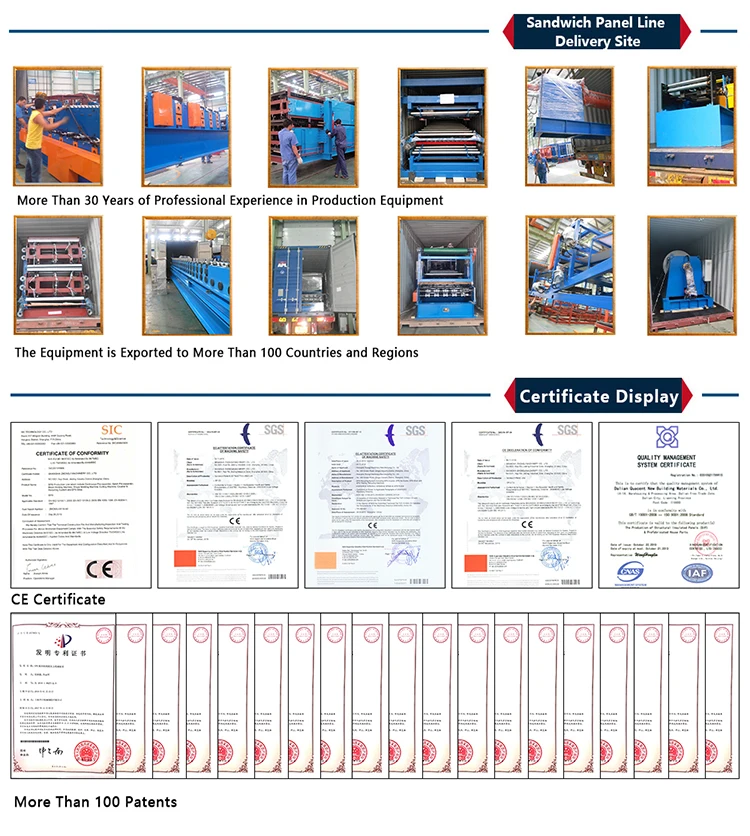

4. การลดราคาสำหรับการขายตรงจากโรงงาน โรงงานขนาด 40,000 ตารางเมตร ประสบการณ์การส่งออก 20 ปี การรับรอง CE สิทธิบัตรมากกว่า 100 รายการ

|

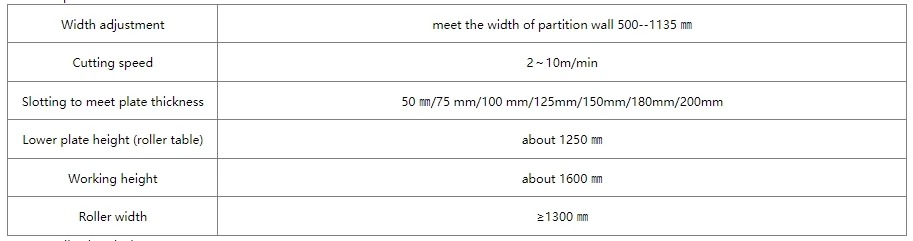

รายการ

|

ชนิด/หน่วย

|

SP-PU-C

|

|

ข้อมูลจำเพาะแผ่นแซนวิชเหล็กเคลือบสี

|

มม

|

ความกว้าง: 700 ~ 1000

ความหนา: 30 ~ 150

|

|

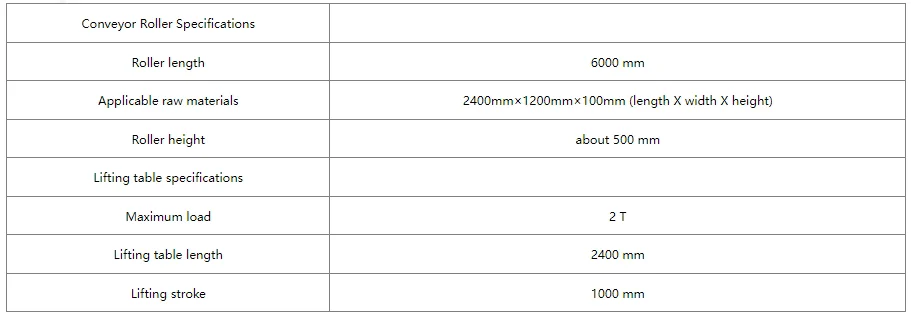

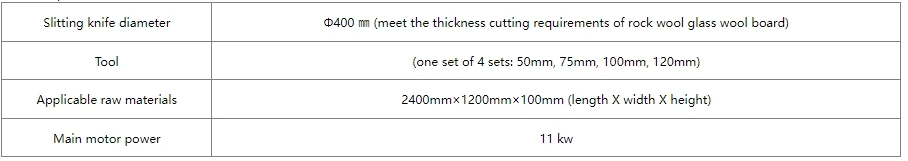

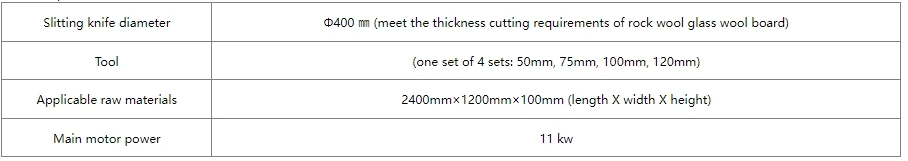

ความเร็วสายการผลิต

|

ม./นาที

|

3~8

|

|

อุณหภูมิสูงสุดของลมร้อนหมุนเวียน

|

°C

|

70

|

|

พลังงานทั้งหมด

|

กิโลวัตต์

|

300

|

|

ขนาดของสาย (L × W × H)

|

มม

|

86000×7000×3800

|

|

กำลังไฟฟ้ารวมที่ติดตั้ง

|

กิโลวัตต์

|

207

|

|

กำลังของเตาอบ

|

แคลอรี

|

200,000

|

|

ความยาวของสายพานลำเลียงแบบสองชั้น

|

M

|

24

|

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ