- Overview

- Inquiry

- Related Products

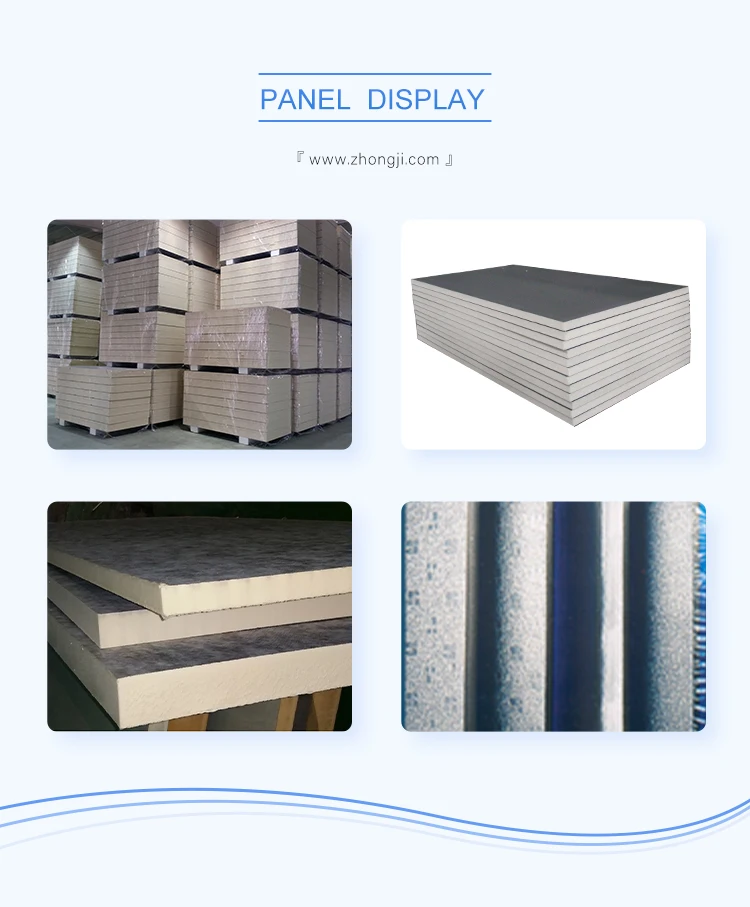

Product Details

1. Zhongji’s high precision manufacturing methods such as its narrow air gap tolerances and vertical offset between the slats as well as the parallelism between upper and lower chain belts are necessary to achieve a high standard of panel surface appearance.

2. For the drive unit of the double belt, two electronically controlled DC type motors have been selected, and are mounted separately on the upper and lower slat chain belt. The motor of the lower belt serves as a pilot drive and is electronically synchronized with the motor of the upper belt to achieve a fully uniform and parallel movement of both slat chain belts. By this electronic synchronization, scratches on panel surface and any decrease of adhesive strength are avoided.

3. By means of several hydraulically operated sets of cylinders, the upper and lower slat chain belts are locked to each other in order to contain the foam’s pressure. Panel thickness is adjusted by exchangeable distance pieces which also serve as limit stops for the upper slat chain belt.

4. The thickness of our slats is over 10~12mm and our slats are the result of our own metal working technology, which assures our product of a 20 year working life with uniform flatness. The slats less than 10mm and without any special metal processing, can not be employed about 2 years after installation. A good quality panel has no variation of thickness, is flat and has no surface scratching,which can be only produced from a highly precise slat.

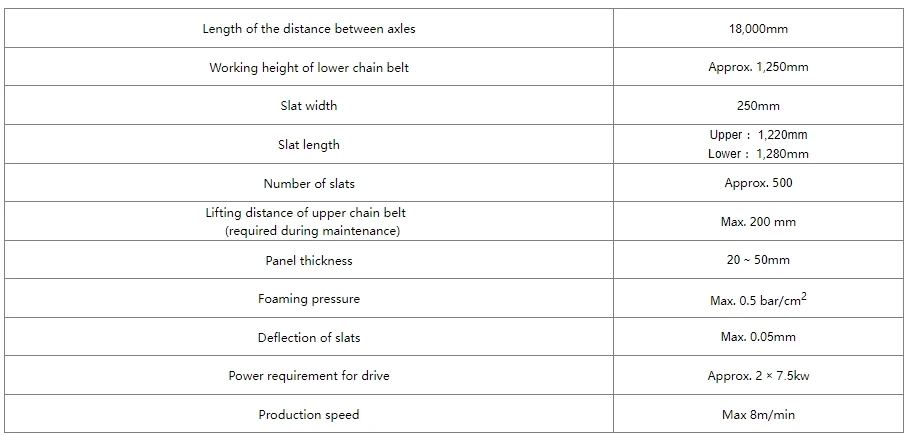

Specifications (Modules):

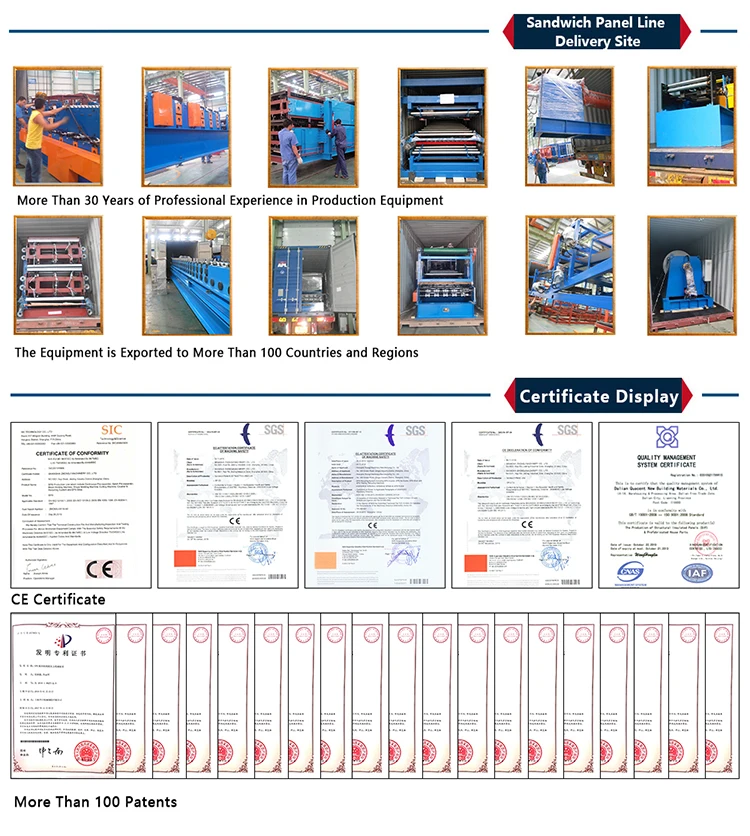

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production

line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Line Dimensions (L × W × H)

|

mm

|

20000 × 50000 × 7000

|

|

Total Power

|

w

|

70000

|

|

Net Weight of Production Line

|

kg

|

70000

|

|

Production Line Speed

|

m/min

|

0-4.5

|

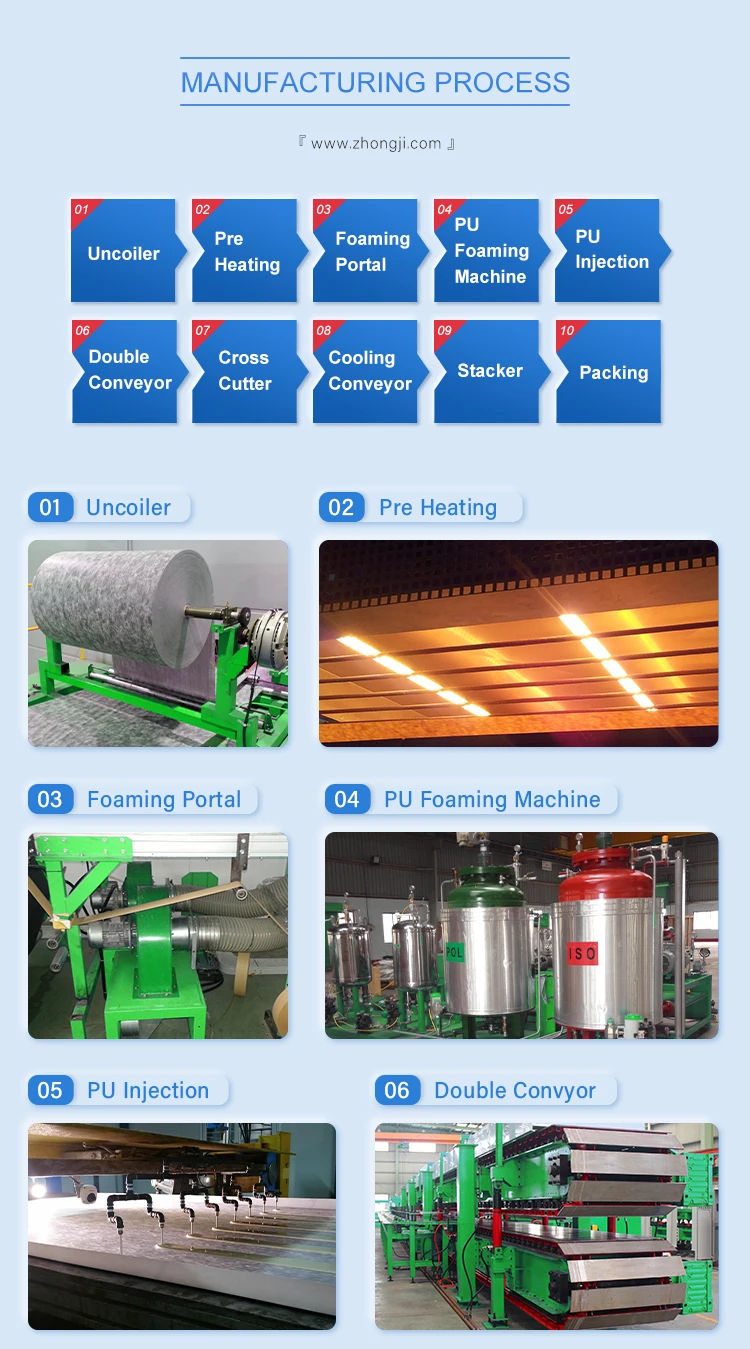

2. We provide three kinds of PU sandwich panel production line as L-type, Straight type, and heads for continuous panel. All of PU sandwich panel production line are available as multi components as 2 to 6 components.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ