- Overview

- Inquiry

- Related Products

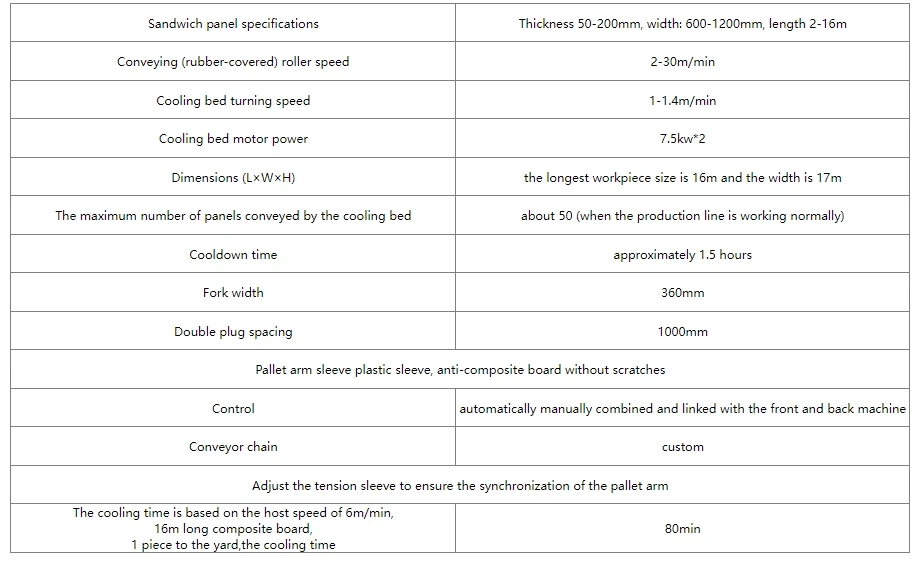

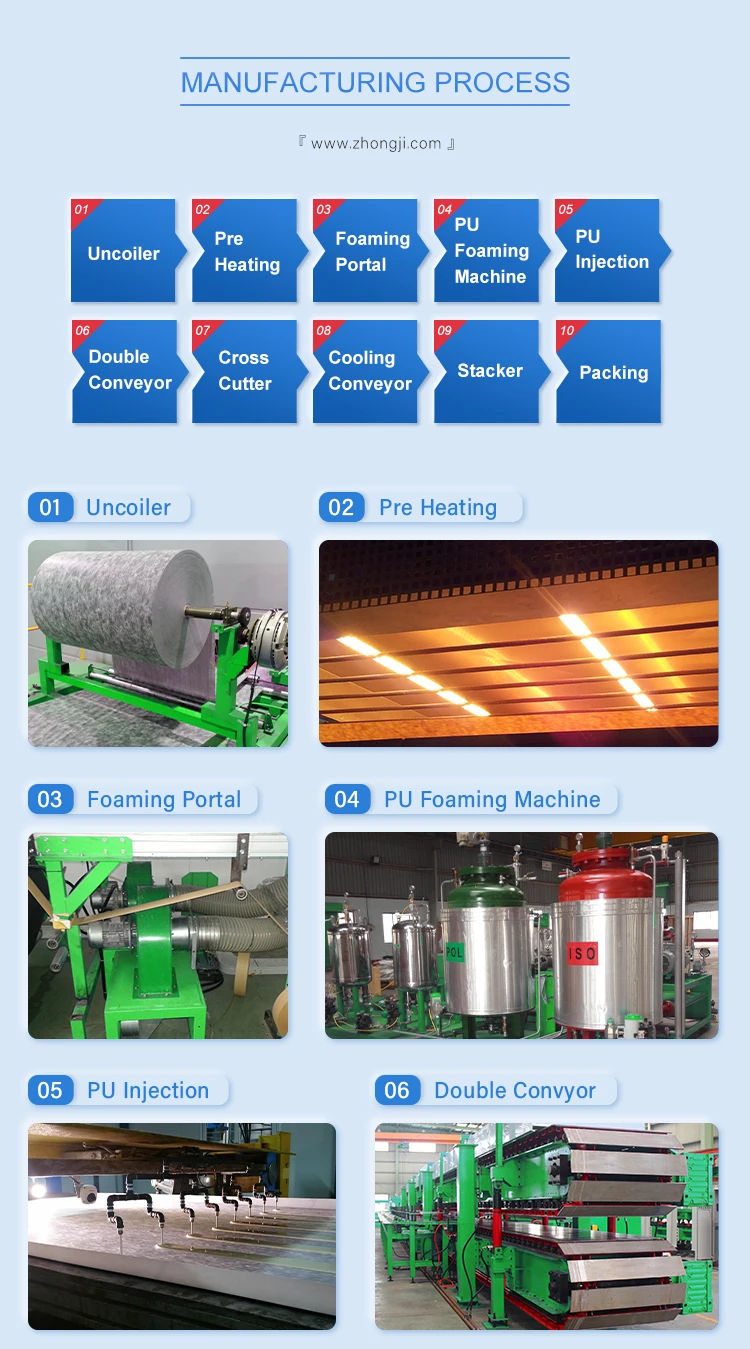

Product Details

1. The main beams of the cooling bed of our company are all processed by gantry, and are connected by bolt positioning keys. The precision is extremely high, and it can bear the 200mm cold storage board for a long time without deformation.

2. Stable operation, good rigidity, three panels can enter and exit at the same time, to achieve the maximum utilization of cooling bed equipment.

3. The sheet passes through the over-roller table to the over-travel roller table 2, and then is transported by the rollers to the upper cooling bed roller table and then transported to the designated position.

4. The lifting mechanism lifts up and down, the synchronous belt transfers the plate laterally to the bottom of the fork, the cool panel spindle controls the plate to turn over about 90°, and the plate on the cool plate process is completed.

5. When the panel is placed under the cooling system, the panel is first turned over to the lower cooling plate roller table by the cooling plate fork assembly, and the plate is moved away from the fork by the outward moving mechanism, and then conveyed to the next process through the transition roller table.

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production

line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

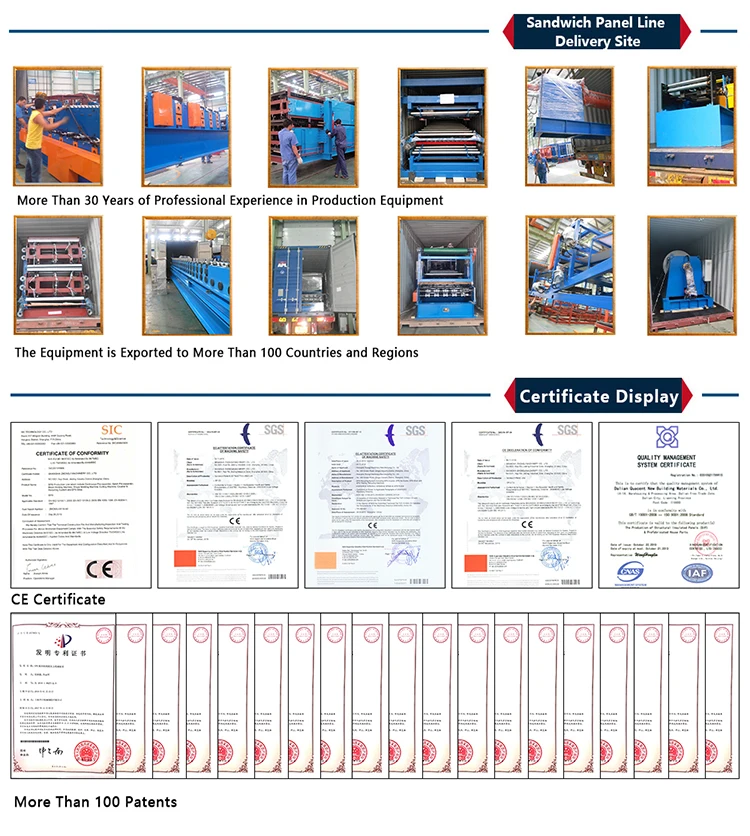

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Line Dimensions (L × W × H)

|

mm

|

20000 × 50000 × 7000

|

|

Total Power

|

w

|

70000

|

|

Net Weight of Production Line

|

kg

|

70000

|

|

Production Line Speed

|

m/min

|

0-4.5

|

2. We provide three kinds of PU sandwich panel production line as L-type, Straight type, and heads for continuous panel. All of PU sandwich panel production line are available as multi components as 2 to 6 components.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ