- Overview

- Inquiry

- Related Products

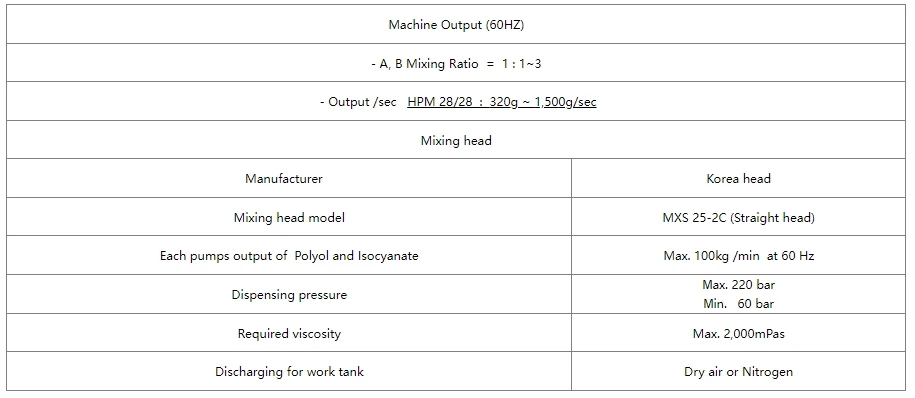

-1 set of piping and flexible hose incl. mixing head,

-1 set of magnetic coupling for Iso only

-2 sets flow meter for Iso and Polyol and display on monitor

-2 sets of pressure gauge for delivery side

Product Details

1. High pressure PUR foaming Machine for 2 components system

There is a common base frame made of welded steel construction for supporting the metering units, filters and electrical pressure switches.

Each metering unit is separately fitted for the Polyol and Isocyanate, and consists of an axial piston pump, coupling, flanged A.C motor, pump support and safety valve.

The pump output can be adjusted infinitely by hand-wheel and scales fitted to the pump housing.

1) Pentane metering unit, explosion proof

-1 double acting metering piston pump

- 1 flow meter, VC0.2

- 4 ball valve

- 1 throttle valve

- 2 pressure gauge

- 1 temperature gauge

- 1 edge filter

- 1 static mixer

- Pentane nozzle/needle assembly

2) Poly metering Unit

- 1 Polyol metering pump, Rexroth A2VK 28

- 1 flow meter, VC 1

- 1 low pressure gauge

- 1 high pressure gauge

- 1 temperature gauges

- 2 ball valve

- 1 edge filter

- 1 motor for polyol

- 1 magnetic coupling for polyol pump

3) Hydraulic Unit for pentane piston

- 1 hydraulic unit, 100Liter

- 1 variable displacement pump

- 1 proportional valve for close loop control

4) Electric Control Unit (Mitsubishi PLC)

5) Gas detector & safety controls ----------- Buyer scope

- 2 gas sensors

- 1 control unit

6) Polyol + C-Pentane Storage tank, 300 Liter

double-walled for temperature control with unpressurized water, made of normal steel,

with stirrer with parallel inspection pipe for optical filling level display

and with possibility for connecting level switches which are adjustable in height ; coml.

With all necessary fittings and accessories as well as connector for Nitrogen filling.

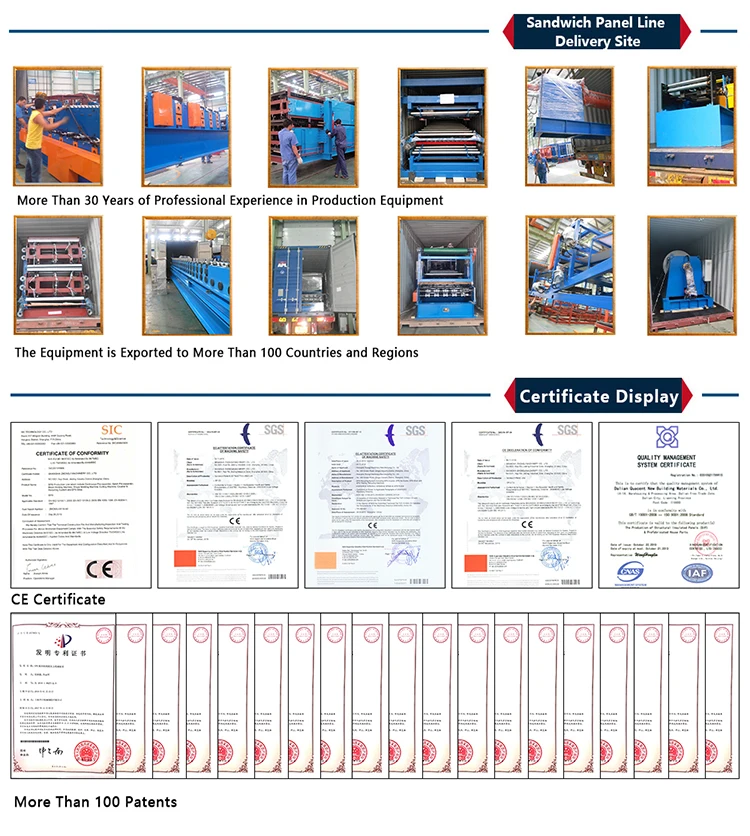

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

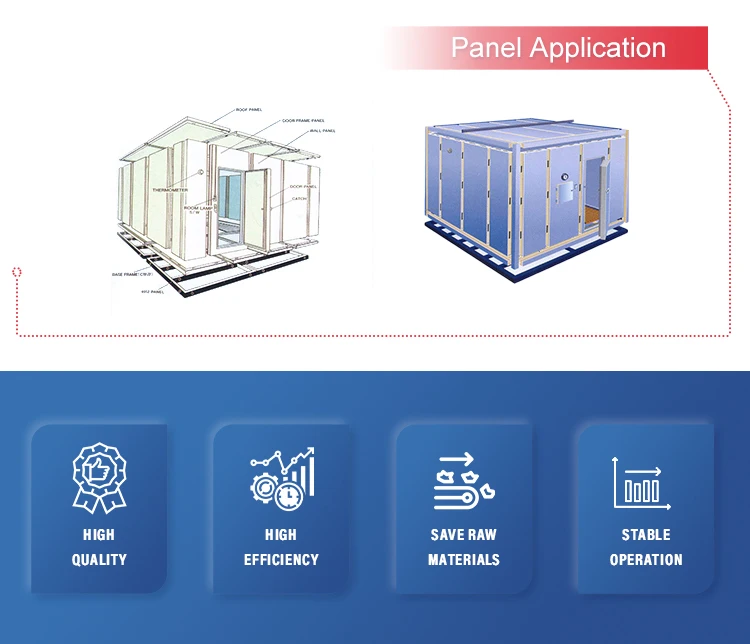

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production

line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Line Dimensions (L × W × H)

|

mm

|

50000×4000×7000

|

|

Production Capacity

|

m²/h

|

2500

|

|

Weight

|

kg

|

80000

|

|

Sheet Thickness

|

mm

|

50-250

|

|

Power

|

w

|

54000

|

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ