- Overview

- Inquiry

- Related Products

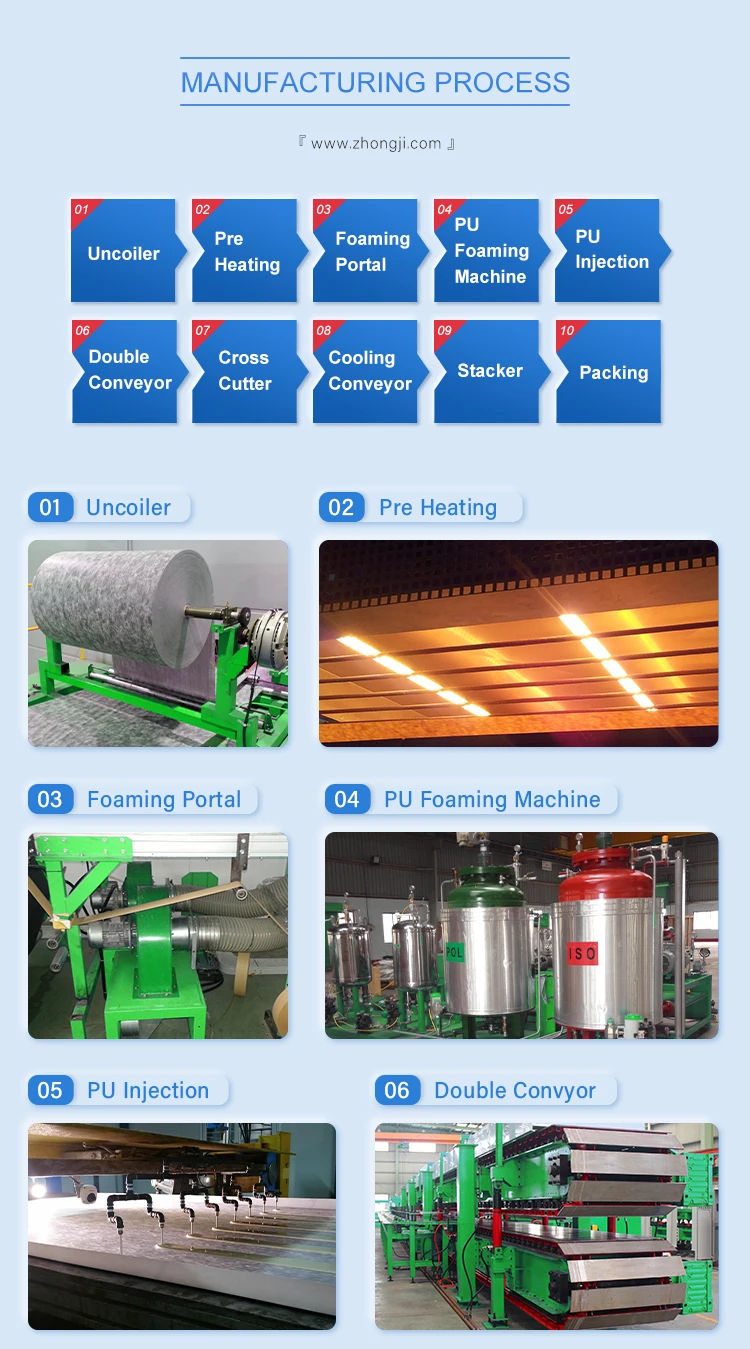

Product Details

1. Material tank:

1) Equipped with 2 1000L material tanks, the inner liner is of stainless steel jacket type, the power of the stirring motor is

11KW, which is used for premixing the resin material.

2) Equipped with a 300L material tank, the inner liner is stainless steel jacket type, used for curing agent.

2. Pump set:

1) One metering pump: gear pump, stepless speed regulation, power 5.5KW, explosion-proof motor.

2) One curing agent metering pump, equipped with a hydraulic diaphragm metering pump, power 0.37KW, explosion-proof motor.

3) A cyclopentane feeding pump: equipped with a hydraulic diaphragm metering pump, power 0.37KW, explosion-proof motor.

4) One phenolic resin feeding pump: equipped with a rotor pump, power 3KW, explosion-proof motor.

3. Mixing head set:

1) A set of mechanical mixing head, mixing speed 4500rpm/min, power 2.2KW explosion-proof motor.

2) Equipped with automatic cleaning device (including a 25L cleaning tank, made of stainless steel).

4. Raw material temperature control system:

Equipped with a 5-hp chiller and corresponding water-liquid electric valve, the real number of material temperature is displayed and adjustable, equipped with a heating water tank, and the power is 6KW. The system can realize automatic control of the raw material temperature.

5. Combustible gas monitoring system:

The combustible gas on the foaming system is detected, equipped with 6 combustible gas control and measuring instruments, which can automatically alarm and activate the exhaust system at the same time to effectively discharge the flammable and explosive gas in time.

Equipped with 2 fans, 6 sets of combustible gas detectors and a set of monitors, with corresponding ventilation ducts.

Fan power 4KW 20000m3/h wind pressure 0.3MPa.

6. Electric control cabinet:

The foaming machine adopts PLC control, and the casting calibration time, cleaning time, blowing time and action program can be preset.

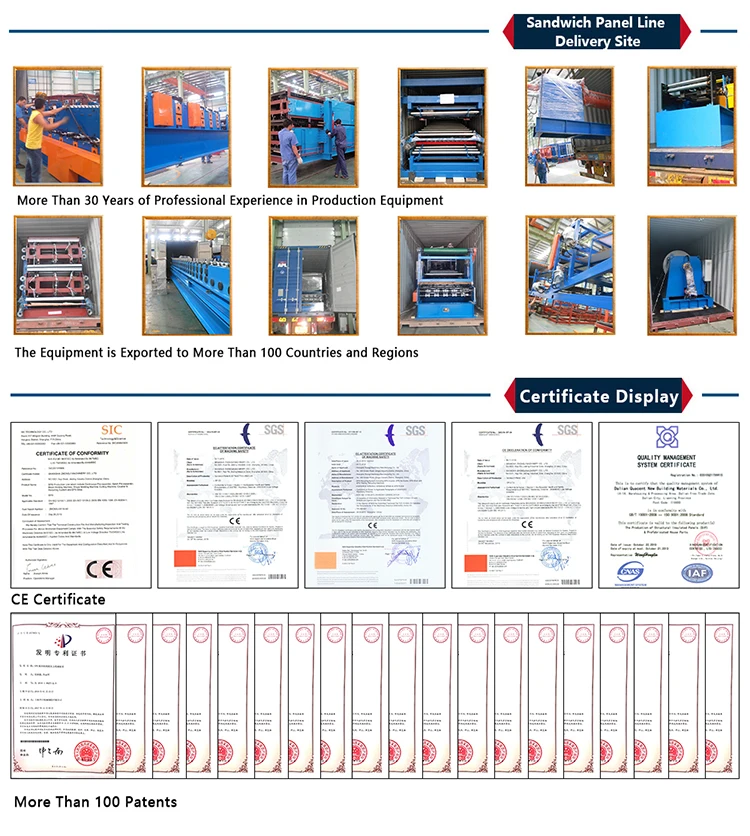

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production

line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Line Dimensions (L × W × H)

|

mm

|

20000 × 50000 × 7000

|

|

Total Power

|

w

|

70000

|

|

Net Weight of Production Line

|

kg

|

70000

|

|

Production Line Speed

|

m/min

|

0-4.5

|

2. We provide three kinds of PU sandwich panel production line as L-type, Straight type, and heads for continuous panel. All of PU sandwich panel production line are available as multi components as 2 to 6 components.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ