- Overview

- Inquiry

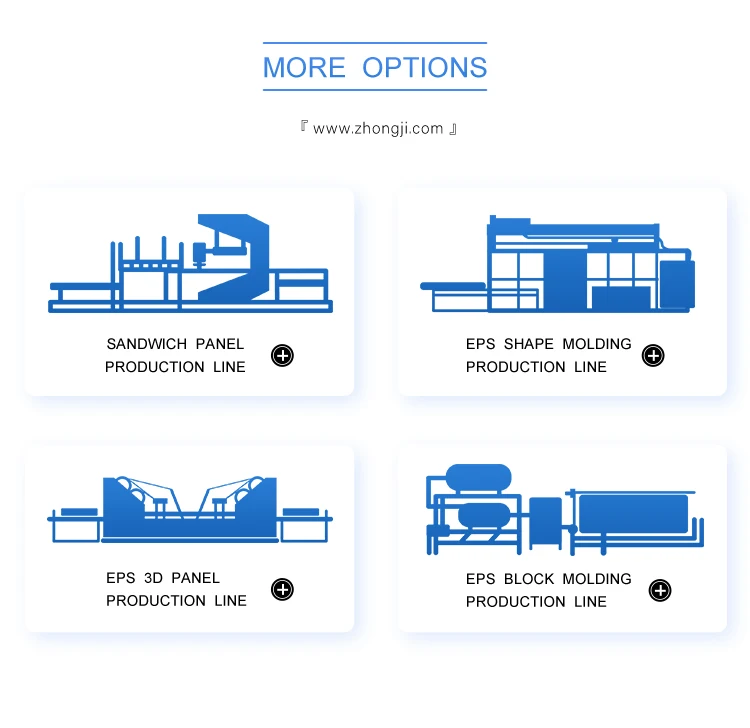

- Related Products

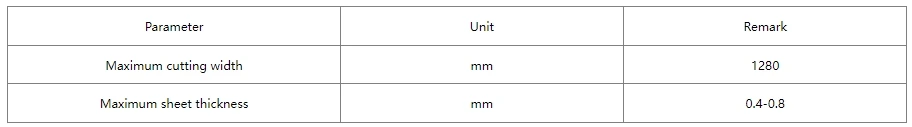

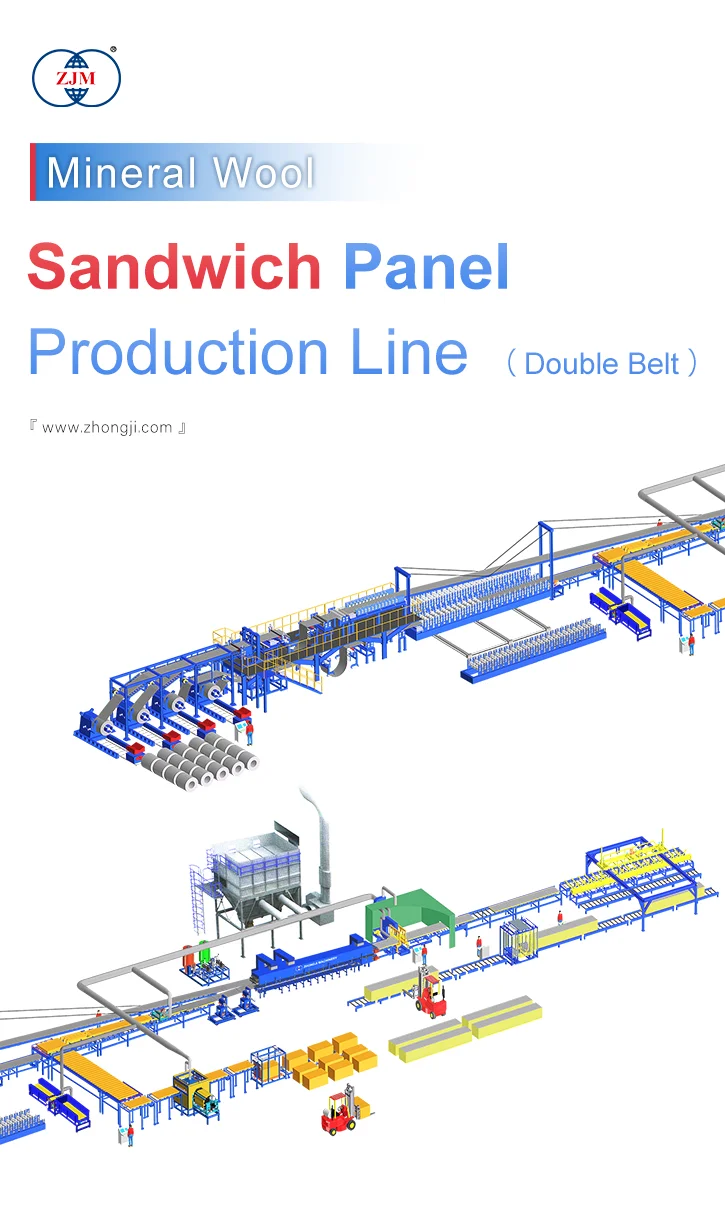

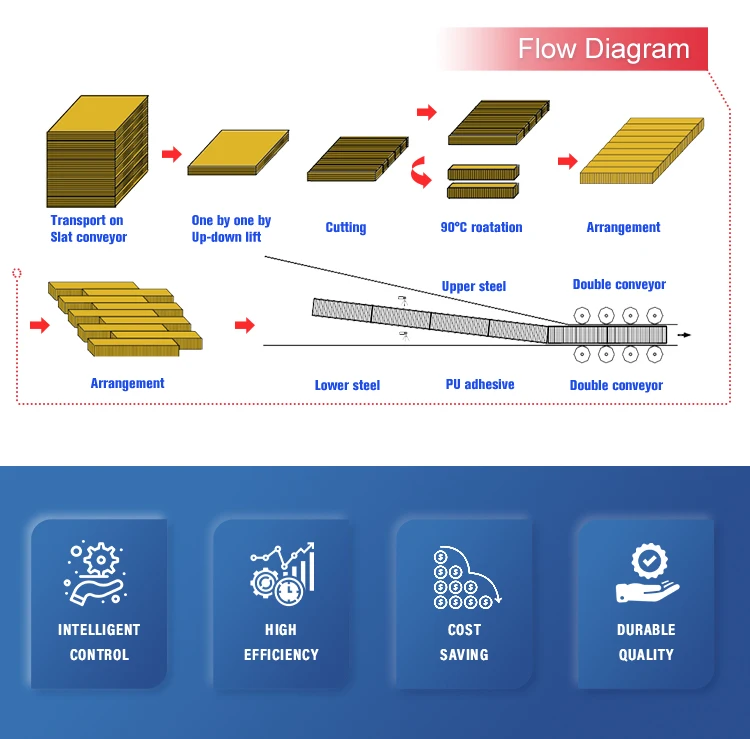

Product Details

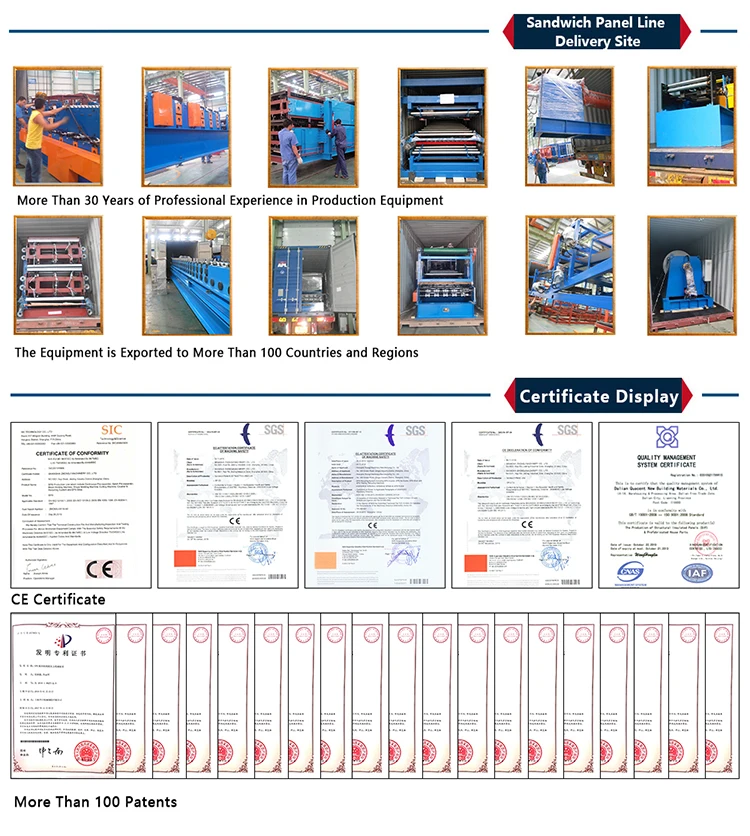

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Production Line Speed

|

m/min

|

5~7

|

|

Total Power of Production Line

|

kw

|

31

|

|

Total Length of Production Line

|

m

|

42

|

|

Net Weight of Production Line

|

ton

|

30

|

|

Thickness of Finished Panel

|

mm

|

50-250

|

|

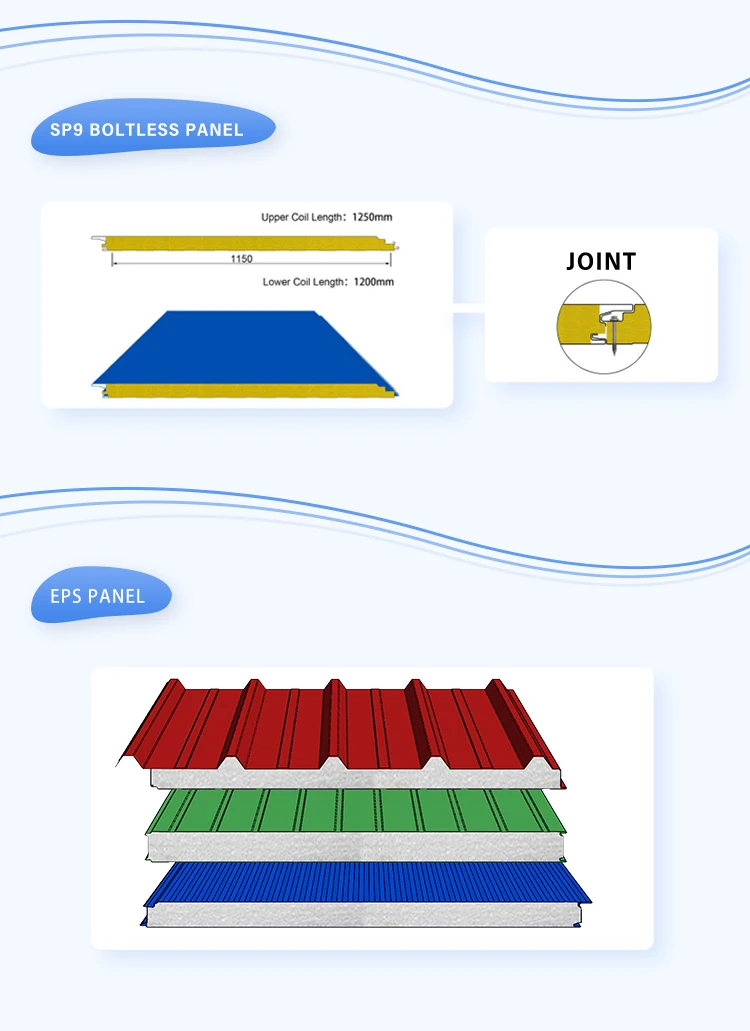

Color Steel Sandwich Panel Specifications

|

mm

|

Width: 1000 ~ 1200

Thickness: 0.2~ 0.8

|

3. The sandwich panel laminator uses rubber-coated roller type laminator to protect the color paint on the colored steel as well as complete during the pressurizing of the sandwich panel.

4. The sandwich panel laminator has a high quality and thick wall rectangular steel welding method, which can get rid of the rust, polishing, smoothing and aging treament.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ