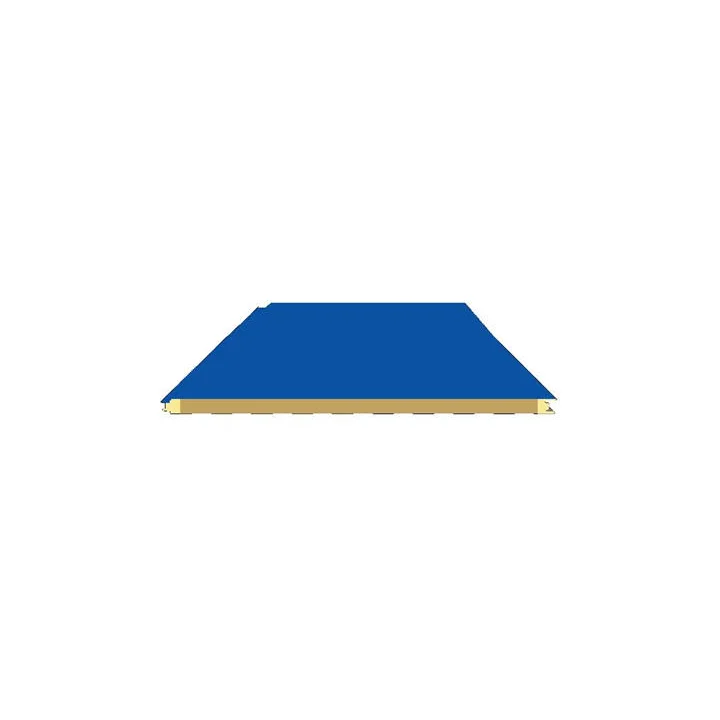

डिसकन्टिन्युअस पीयू स्प्रे फोम सैंडविच पैनल लाइन बहुत विशेष छ, जो पारंपरिक उत्पादन तरीकाको मुल्याङ्कनभन्दा बढी छ। यसले तिनीहरूलाई धेरै पैनलहरूलाई तेजै-तेजै बनाउन सक्दैछ। यी मजबूत र स्थिर पैनलहरू कामगारीको अद्वितीय गुणस्तरमा बहुमुखी हुन्। यो कुनै पनि भण्डारण इमारत, गोदामहरू वा घरहरूसँग जोडिएको छ, जसलाई एक व्यक्तिले बस्ने गर्छ।

यो मशीन साथै धेरै तेज छ। विशेष गर्दा, यदि यो धेरै कुशल छ, त्यसैले तपाईंलाई हाम्रो ग्रहको साथमा सही रूपमा काम गर्न ठूलो ऊर्जा प्रयोग गर्न आवश्यक छैन। यस मशीनको फाइदा यो हो कि यो उच्च गतिमा काम गर्दछ, जसले कम्पनीलाई समय र पैसा बचाउन मदद गर्दछ जबकि बढी गुणस्तरमा राम्रो पैनलहरू उत्पादन गर्न सक्दछ। यो कम्पनीहरूलाई सफल हुनको अलावा पनि पर्यावरणको देखभाल गर्नका लागि महत्वपूर्ण छ।

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ