- 概要

- 問い合わせ

- 関連製品

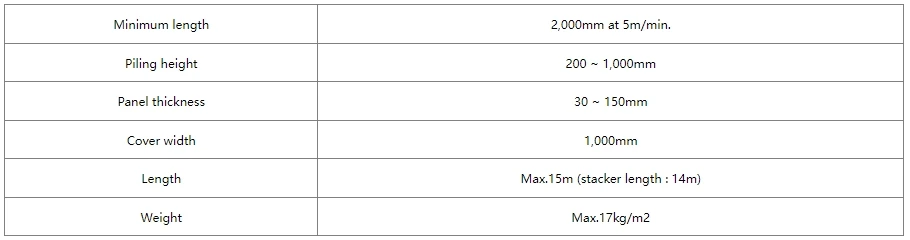

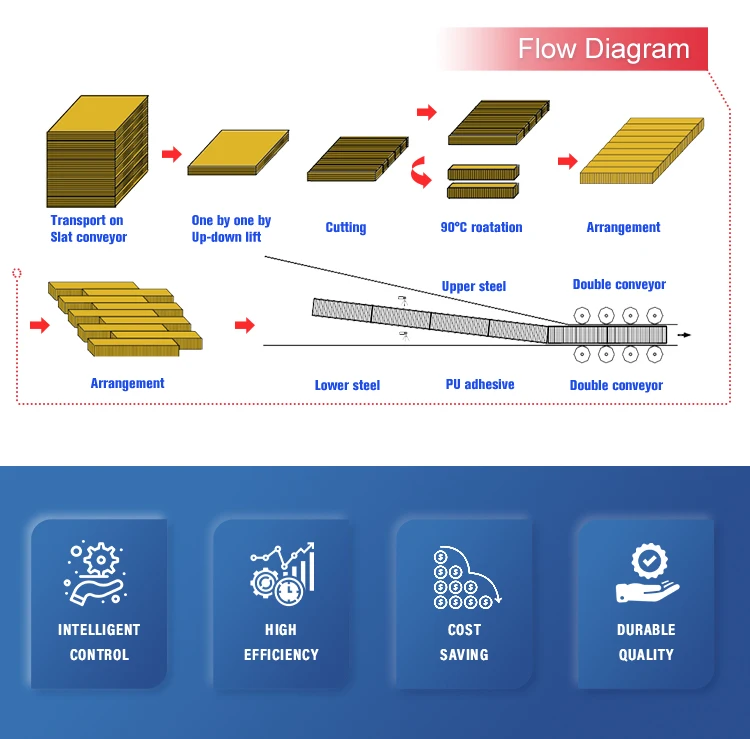

このプロセスは、生産速度に合わせて仕上げられたパネルを効率的に積み重ねるためのものです。

積み重ねる速度がパネルの生産速度よりも遅くならないことは非常に重要です。

自動または手動でパネルを積むことが可能です。

スタッカー容量:

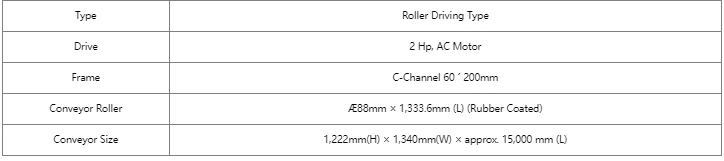

1. 高速コンベヤー

クロスカッターからストッパー・コンベヤーへ単一のパネルを高速で搬送します。

クロスカッターからストッパー・コンベヤーへ単一のパネルを高速で搬送します。

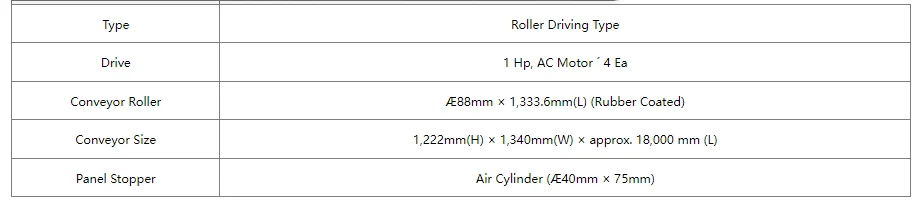

2. ストッパー・コンベヤー

このユニットは、高速から来たパネルがスタッカーに持ち上げられるまでの最後のコンベヤーであり、最大サイズをカバーできます。

18mのパネル長。高速で移動するパネルをスムーズに停止させるための停止装置が付いています。

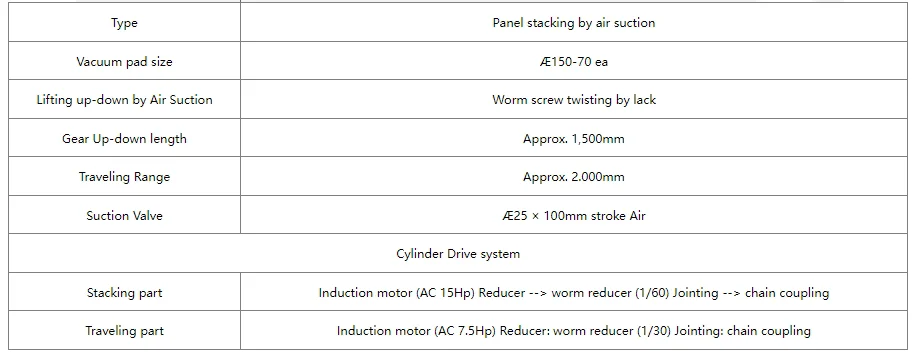

3. スタッカー

このユニットは、真空パッドでパネルを吸着しながら、ストッパーコンベヤーからスタックコンベヤーまたは可動パレットにパネルを搬送します。

このユニットは、真空パッドでパネルを吸着しながら、ストッパーコンベヤーからスタックコンベヤーまたは可動パレットにパネルを搬送します。

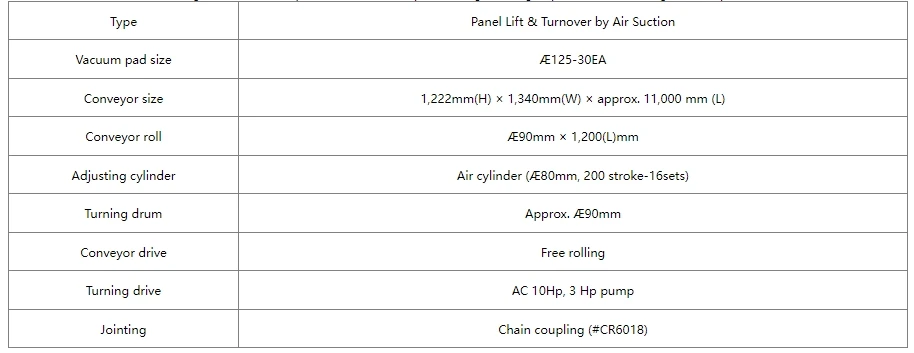

4. 反転装置

このユニットは屋根パネルを反転させ(180度回転させ)、パネルを効率的に積み重ねてスペースを節約し、 互いに屋根パネルを収納します。

このユニットは屋根パネルを反転させ(180度回転させ)、パネルを効率的に積み重ねてスペースを節約し、 互いに屋根パネルを収納します。

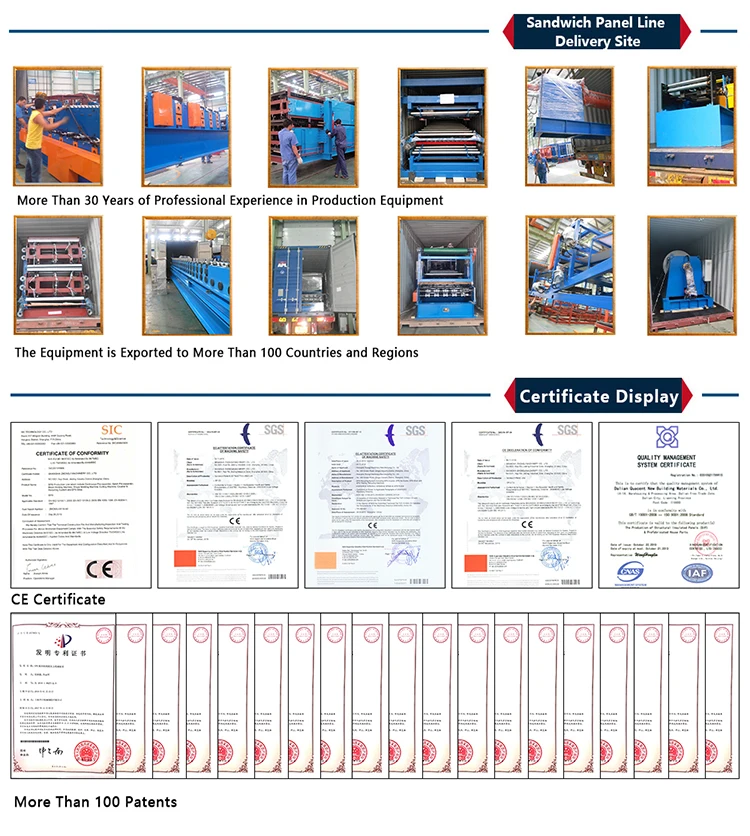

会社およびサービスの優位性:

1. 会社の工場は40,000平方メートルで、トップクラスの多機能加工センター、CNC旋盤、CNCミリングマシンなどの高精度加工設備を導入しています。例えば、450万円相当の3m×8mのガントリ加工センターや、3億円相当の2.5m×12mのガントリミリングマシンなどがあります。

2. 会社には専門の調整チームがあり、24時間対応のアフターサービスを提供しています。

(1) インストールと調整

設備は当社の平面レイアウトに従って顧客の工場に到着しました。経験豊富な技術者を派遣し、設備の設置、調整、試作生産を行い、生産ラインの定格生産能力に達するよう設備を整えます。

(2) トレーニング

弊社は顧客に対して技術研修を提供しています。研修内容には、設備の構造とメンテナンス、設備の制御と操作が含まれます。経験豊富な技術者が指導し、研修プログラムを確立します。研修後、購入者の技術者は設備の操作とメンテナンスを習得し、プロセスを調整し、さまざまな故障に対処できるようになります。

3. 售後サービスにおいて品質問題が発生した場合、2時間以内に回答します。電話やビデオによる遠隔指導で解決できない場合は、国内であれば24時間以内にエンジニアを現場に派遣して問題を解決します。

4. 工場直販価格での割引、40,000平方メートルの工場を有し、20年間の輸出企業、CE認証取得、特許100件以上保有。

2. 会社には専門の調整チームがあり、24時間対応のアフターサービスを提供しています。

(1) インストールと調整

設備は当社の平面レイアウトに従って顧客の工場に到着しました。経験豊富な技術者を派遣し、設備の設置、調整、試作生産を行い、生産ラインの定格生産能力に達するよう設備を整えます。

(2) トレーニング

弊社は顧客に対して技術研修を提供しています。研修内容には、設備の構造とメンテナンス、設備の制御と操作が含まれます。経験豊富な技術者が指導し、研修プログラムを確立します。研修後、購入者の技術者は設備の操作とメンテナンスを習得し、プロセスを調整し、さまざまな故障に対処できるようになります。

3. 售後サービスにおいて品質問題が発生した場合、2時間以内に回答します。電話やビデオによる遠隔指導で解決できない場合は、国内であれば24時間以内にエンジニアを現場に派遣して問題を解決します。

4. 工場直販価格での割引、40,000平方メートルの工場を有し、20年間の輸出企業、CE認証取得、特許100件以上保有。

|

アイテム

|

タイプ/ユニット

|

SP-PU-C

|

|

生産ライン速度

|

m/min<br>

|

5~7

|

|

生産ラインの総電力

|

KW

|

31

|

|

生産ラインの全長

|

m

|

42

|

|

生産ラインの純重量

|

トン

|

30

|

|

完成パネルの厚さ

|

mm

|

50-250

|

|

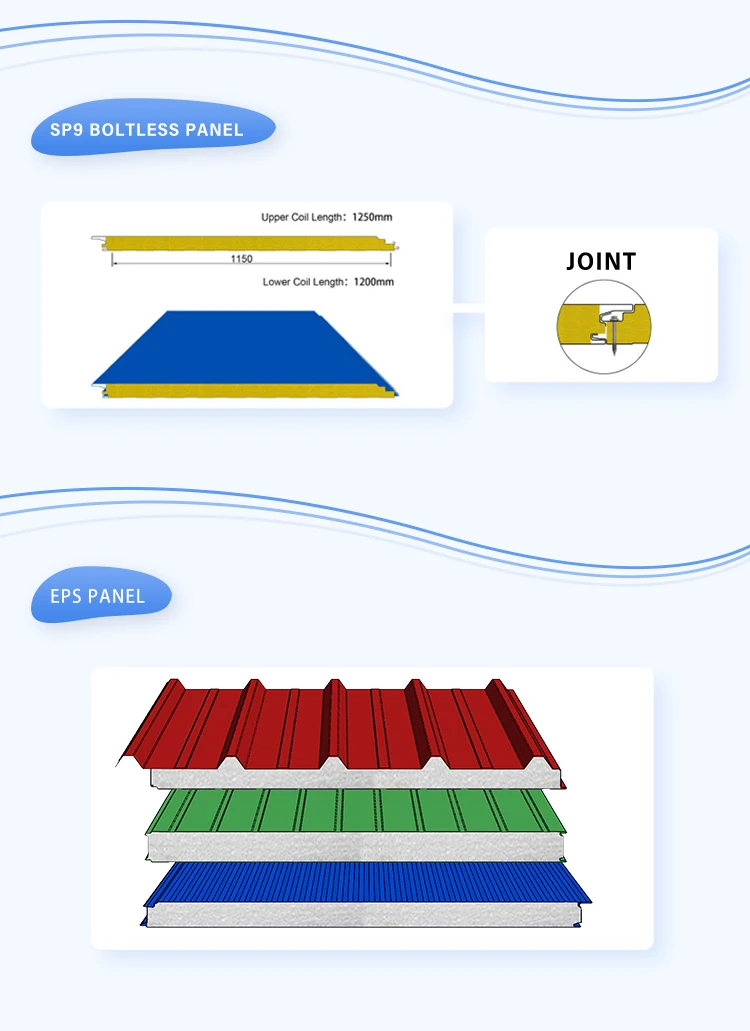

カラースチールサンドイッチパネル仕様

|

mm

|

幅: 1000 ~ 1200

厚さ: 0.2~ 0.8

|

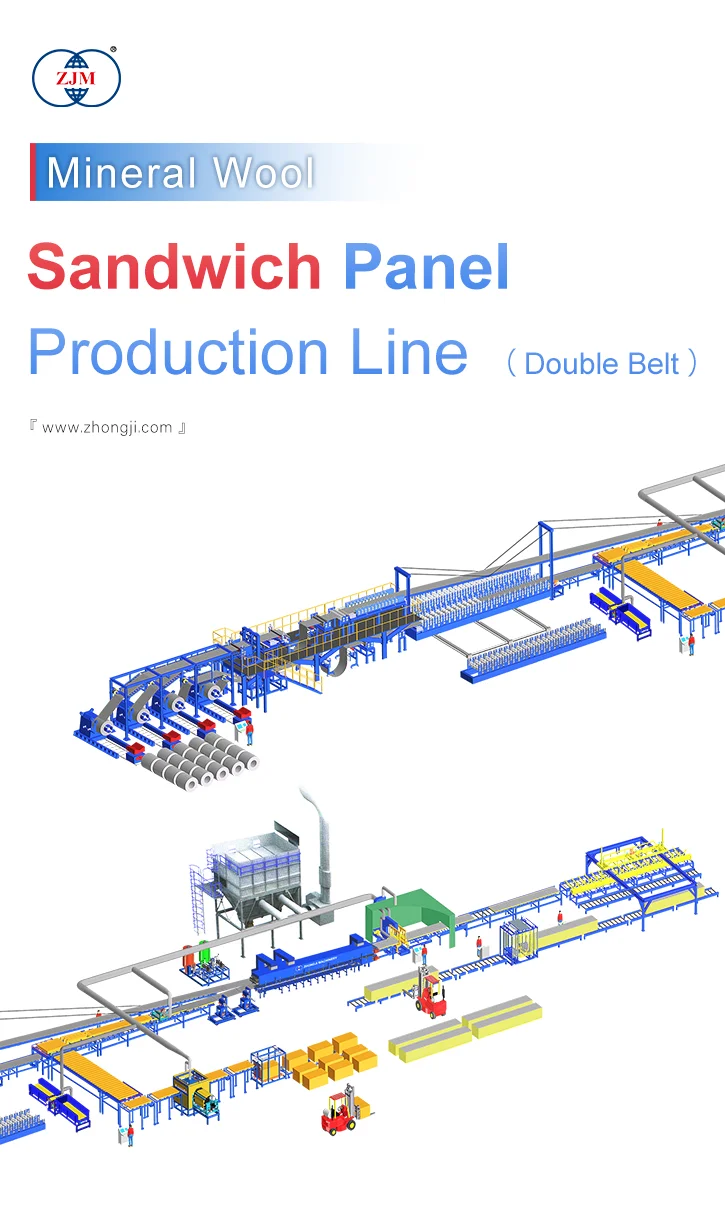

1. サンドイッチパネルラミネーターの伝動はワームギア伝動システムを使用しており、ラミネート速度が確保されます 安定しており、層圧が均一です。

2. サンドイッチパネル層圧機は、周波数調整器を使用して、事前に設定されたサンドイッチパネルの長さに応じて自動的にカットします。

3. サンドイッチパネル層圧機は、彩色鋼板の色塗装を保護するためにゴムコーティングローラータイプの層圧機を使用します。また、 完成 サンドイッチパネルを加圧する際も同様です。

4. サンドイッチパネル層圧機は、高品質で厚い壁の矩形鋼溶接方式を採用しており、錆取り、研磨、平滑化、および老化処理を行うことができます。

3. サンドイッチパネル層圧機は、彩色鋼板の色塗装を保護するためにゴムコーティングローラータイプの層圧機を使用します。また、 完成 サンドイッチパネルを加圧する際も同様です。

4. サンドイッチパネル層圧機は、高品質で厚い壁の矩形鋼溶接方式を採用しており、錆取り、研磨、平滑化、および老化処理を行うことができます。

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ