- Overview

- Inquiry

- Related Products

Zhongji's Highly Durable Easy to Operate Stacking Machine is the perfect solution in your stacking requirements. This machine is strong and built to last, rendering it a good investment is excellent in any business. Its durability means that it shall last to the most challenging of tasks and continue to run efficiently for years in the future.

Operating the gear could never be easier. It absolutely was made out of ease of use in your mind, therefore even those without having the experience can run it with simplicity. Its user-friendly software helps to ensure that all essential controls are often close at hand, permitting a process anyone is simplified master. This will make it a choice is very good companies which have a high staff return as it minimizes the amount of training required.

Among the many items that are excellent, the Zhongji definitely Durable and Easy to use Stacking Machine items quickly, efficiently and effortlessly. Its design actually enables you to ensure that items are stacked in an everyday and stable assisting to optimize room effectiveness and minimize harm item. This might effortlessly ensure a selection of organizations handle fragile or things that is expensive.

Also, the Zhongji Highly Durable Easy to Operate Stacking Machine is versatile, and different number can be managed as a result of it of varied product types, kinds, and sizes. Its adaptability guarantees any stacking are handled as a total consequence of it task, from little products to bigger things.

The gear can be a task that is easy maintain, requiring minimal upkeep. This decreases downtime and insures basic constantly runs effectively and efficiently, assisting businesses reduce general expenses and enhance efficiency.

The Zhongji Highly Durable Easy to Operate Stacking Machine happens to be created for worker utilizing in your mind. It features safety to attenuate the chance of accidents and injuries during procedure. This assists companies which can be certain produce a safer working environment for his or her workers while making one of the most of effectiveness.

Product Details

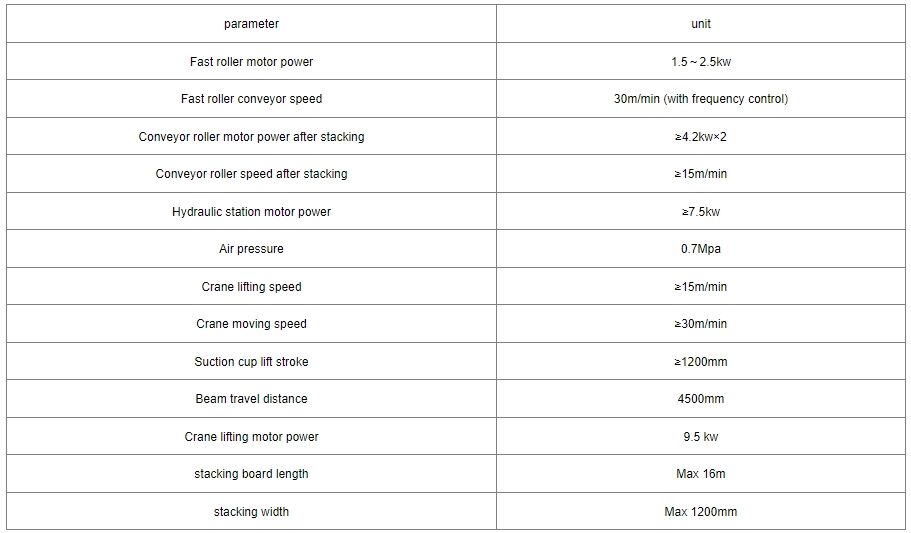

1. This process effectively stacks the finished products on the premise of meeting the production speed.

2. The key point is that the stacking speed must be faster than the production speed.

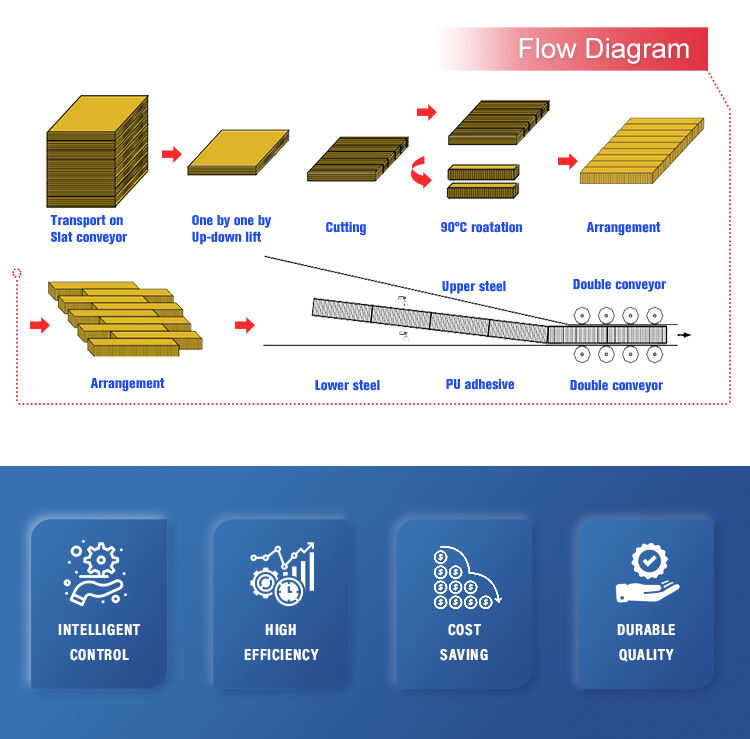

3. The completed sheet (veneer) is conveyed and cut at high speed from the cross-cutting point to the stopper wire body.

4. The cutted panels are stacked one by one in the stacking area after passing through the stopper line. The stacked panels are automatically transferred to the packing line by the sliding assembly line (entering the line).

5. The stacking consists of high-speed moving conveyor rollers, high-speed conveyor parking device, roof panel turning device, horizontal push stacker, and conveyor rollers. The roof panel turning device can turn the odd-numbered roof panels by 180°, so that the corrugated matching of the panels saves space and doubles the stacking efficiency. The stacked panels are transported to the packing machine by conveying rollers.

6. Features: It adopts the form of push plate, and the manipulator holds the rotation mode:

During the first unloading, the surface of the board is not stressed, which protects the quality of the board surface and avoids the damage to the board surface caused by the traditional suction cup palletizing of polyurethane (mineral wool) composite boards with a thickness of more than 100mm.

The second is to avoid the phenomenon of air leakage and falling of small corrugated boards with suction cups. The stacker configured in the production line adopts a disc electric rotating device, which must be safe and reliable. When the power is cut off and the air source is cut off at the same time, the lifting roller table, the clamping device, and the roller table can still keep the workpiece in its original state, and the power is self-locking. It is easy to restore

7. Power-on and ventilation or manual processing, safe and reliable.

8. The stacking machine is turned over by adjusting the frequency converter to make the acceleration and deceleration smooth.After reaching the predetermined position, it will brake quickly and position accurately. The rollover roller table and push plate device are stable and reliable, and the stacking is neat.

Company and Service Advantages:

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production

line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

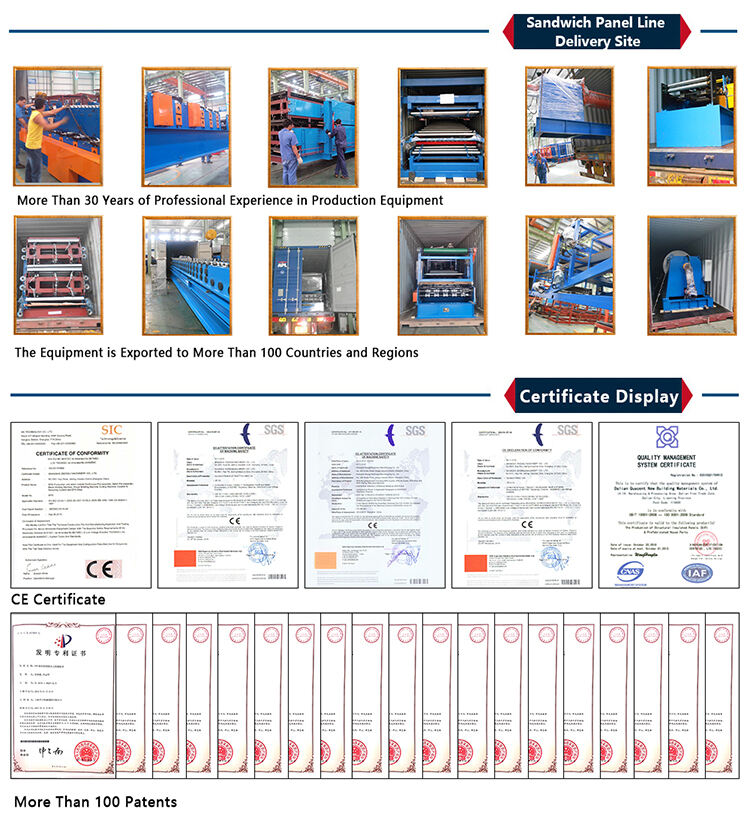

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ