- Overview

- Inquiry

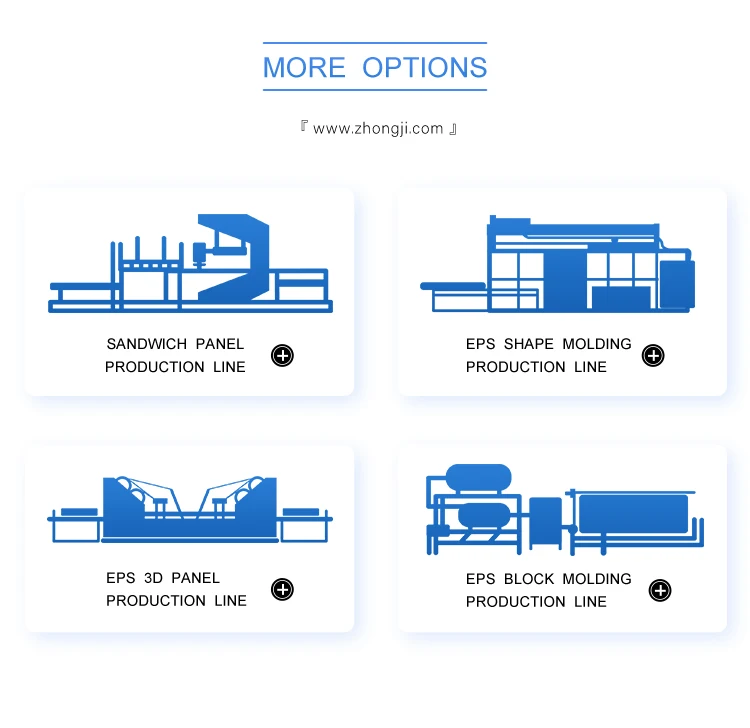

- Related Products

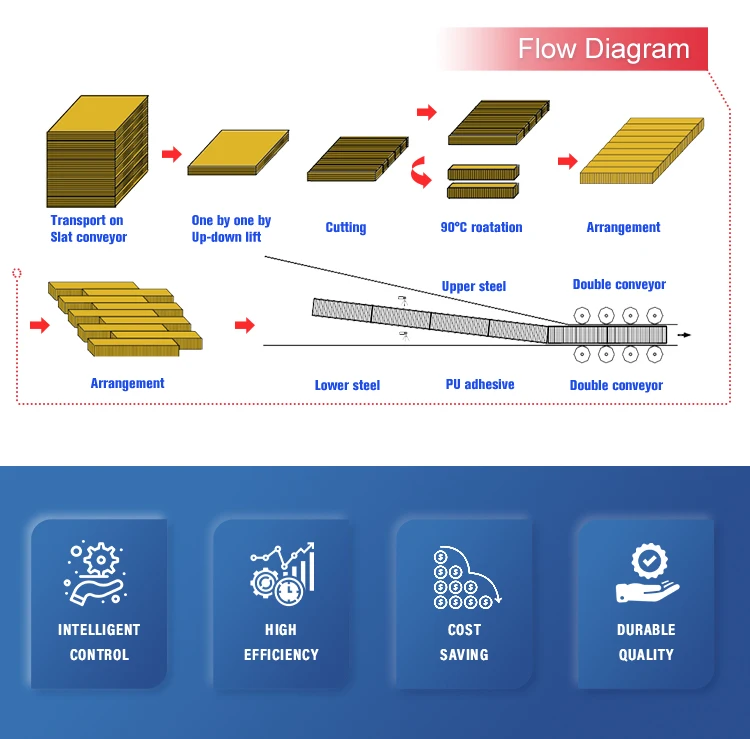

The laminator composite high-strength metal materials on the double-sided outer layers of the thermal insulation inner core mat

Product Details

1. Metal surface thermal insulation sandwich panel is an ideal material for multi-functional new construction and decoration. It has various superior properties such as heat preservation, fire prevention, decoration, etc. It can be used in public buildings such as industrial plants, supermarkets, large warehouses, large-span roofs, simple temporary houses, etc. It can also be used in various cold storages, clean rooms, air conditioning rooms, communications Base stations, etc.

2. Due to its advantages of high strength, beautiful appearance, convenient construction and short construction period, it has become an ideal new building material among today's building materials, and is widely used.

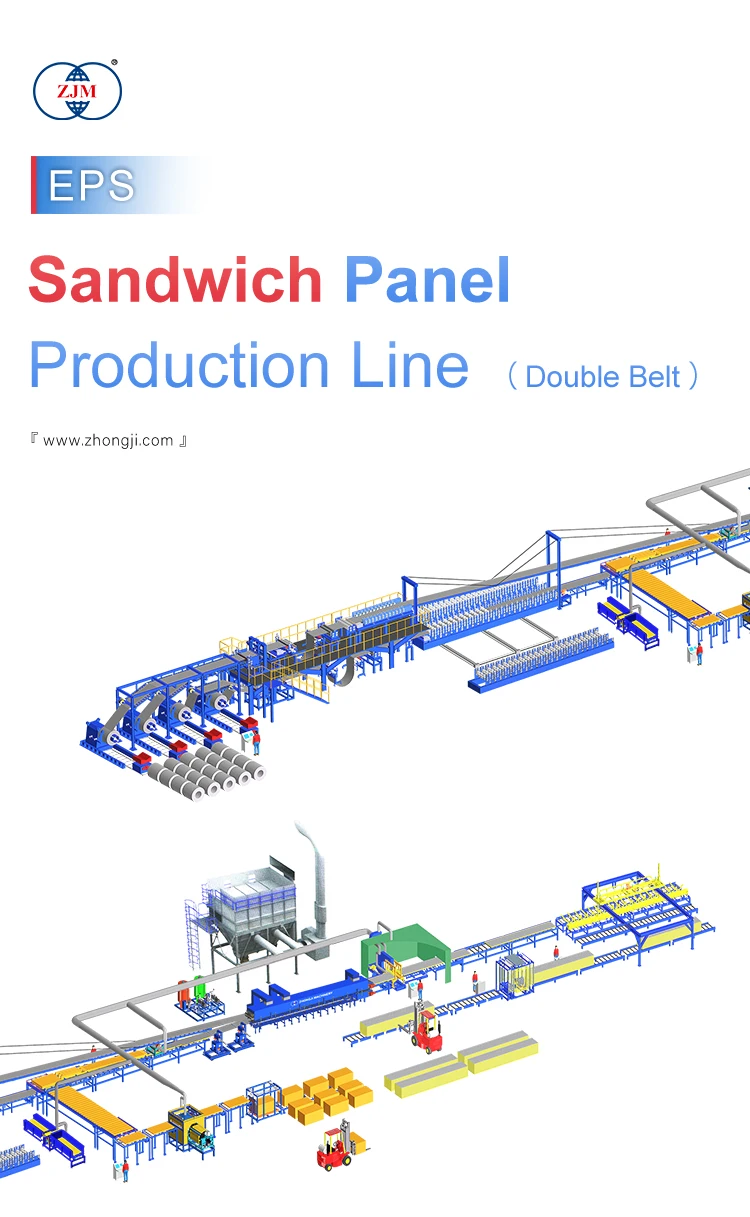

3. According to the current development trend of international and domestic color steel plate, our company designs and manufactures SP-5 color steel plate production line according to customer needs.

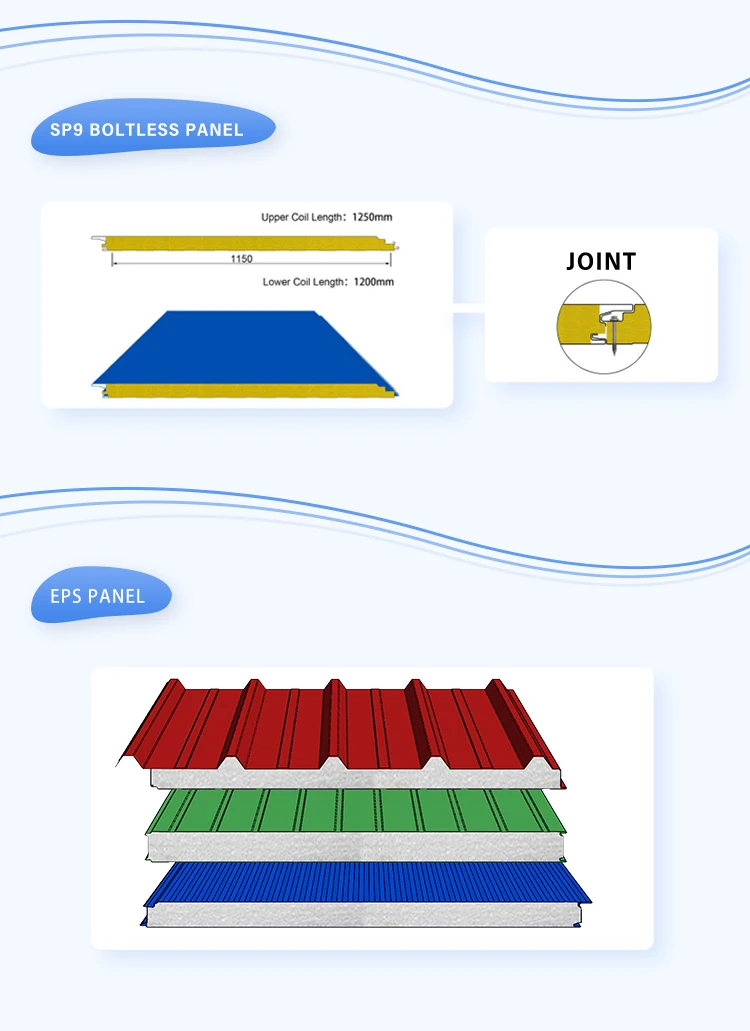

4. The unit can produce various types of sandwich panels with polystyrene foam as core materials, socket panels and other types of sandwich panels. The sandwich panels should comply with GB/T23932 -2009 National Standard of the People's Republic of China.

5. The compounding unit includes complete sets of equipment for color steel plate uncoiling, forming, feeding, main machine compounding, finished product cutting, and conveying racks.

6. The fixed-length counting device is adopted to realize the continuous automatic control of the whole unit, which makes the unit easy to operate and reliable in performance. Then Zhongji SP-5 EPS Sandwich Panel Production Line is the perfect solution if you are looking for a reliable and efficient

solution to create EPS sandwich panels for you personally. The item this is certainly top-quality manufactured by Zhongji, one of

the leading manufacturers of construction machinery on earth.

The SP-5 EPS Sandwich Panel Production Line was meant to make sandwich panels employed for the choice of purposes, including walls

which will be roofing that is building and floors. The panel line that is manufacturing of several elements, including a roll

developing system, a property heating, and a method that is cutting. These elements meet up seamlessly to come up with sandwich

that is top-notch that meet up with the strictest industry criteria.

One of the main benefits of utilizing the Zhongji SP-5 EPS Sandwich Panel Production Line is its effectiveness. The merchandise is

wholly automatic, which means that it may quickly produce sandwich panels and with minimal intervention this is certainly

individual. This decreases work expenses and increases manufacturing that is manufacturing making this a choice that is good

organizations that need to create large volumes of sandwich panels.

A plus this is certainly additional the SP-5 EPS Sandwich Panel Production Line is its versatility. This product can produce

panels in a selection of different sizes and thicknesses, and thus you can use it for a number of different jobs. Additionally,

the panels may be produced from many different materials, including steel, aluminum, and PVC.

The Zhongji SP-5 EPS Sandwich Panel manufacturing Line is rate that is first regards to quality. The machine was created to

generate panels being strong, durable, and lightweight, making them suitable for used in several different construction jobs.

Additionally, all of the various elements of the functional system are created from top-notch materials, making certain the item

can last for years with only maintenance that is minimal.

Overall, then Zhongji SP-5 EPS Sandwich Panel Production Line may be the perfect solution if you ought to be interested in a

top-notch and efficient approach to create EPS sandwich panels. This method is just a must-have for every company in the

construction industry featuring its reliable performance, flexibility, and quality construction.

Company and Service Advantages:

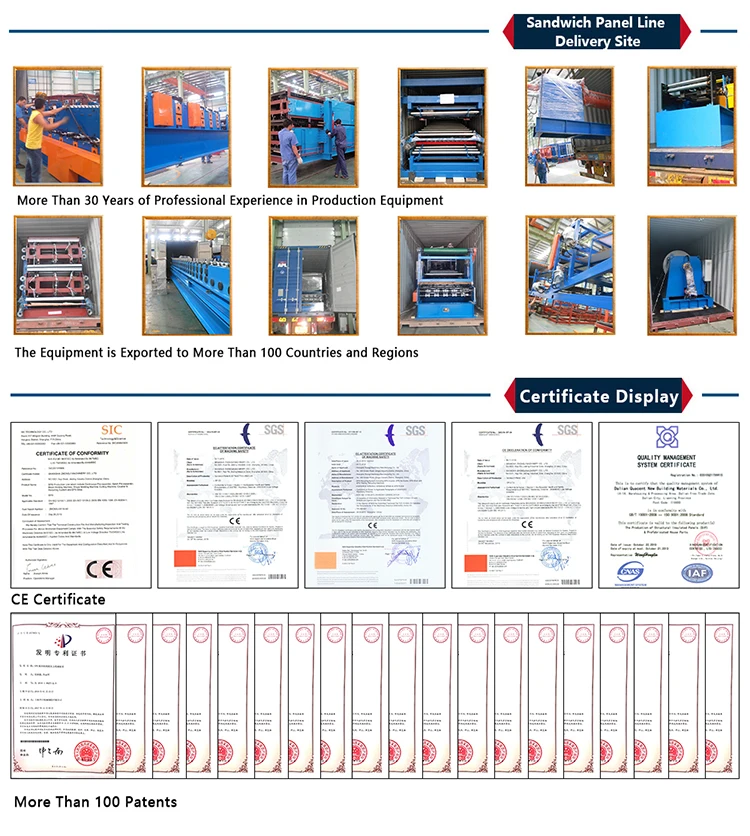

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 100 items.

|

ITEMS

|

TYPE/UNIT

|

SP-PU-C

|

|

Production Line Speed

|

m/min

|

5~7

|

|

Total Power of Production Line

|

kw

|

31

|

|

Total Length of Production Line

|

m

|

42

|

|

Net Weight of Production Line

|

ton

|

30

|

|

Thickness of Finished Panel

|

mm

|

50-250

|

|

Color Steel Sandwich Panel Specifications

|

mm

|

Width: 1000 ~ 1200

Thickness: 0.2~ 0.8

|

3. The sandwich panel laminator uses rubber-coated roller type laminator to protect the color paint on the colored steel as well as complete during the pressurizing of the sandwich panel.

4. The sandwich panel laminator has a high quality and thick wall rectangular steel welding method, which can get rid of the rust, polishing, smoothing and aging treament.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ