Unternehmens- und Servicevorteile:

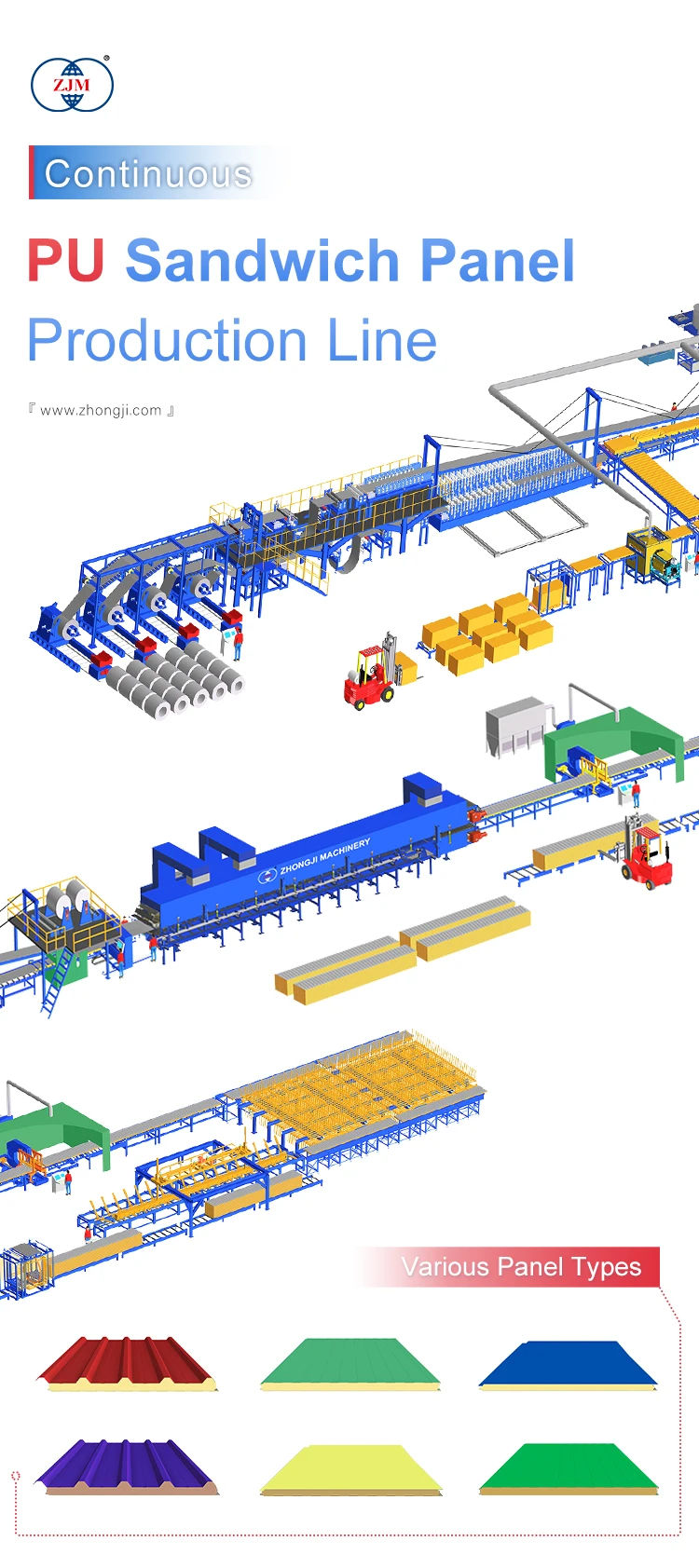

1. Das Werk der Firma umfasst 40.000 Quadratmeter und verfügt über erstklassige Mehrspindel-Fräse, CNC-Drehschneiden, CNC-Fräser und andere hochpräzise Bearbeitungsausrüstungen. Zum Beispiel die 4,5 Millionen Yuan wertige Gantry-Fräse mit 3mx8m und die 300 Millionen Yuan teure Gantry-Hobelmaschine mit 2,5mx12m.

2. Das Unternehmen verfügt über ein professionelles Einstellteam, das rund um die Uhr einen unaufhörlichen Kundendienst bietet.

Installation und Einstellung

Das Gerät ist im Werk des Kunden eingetroffen, gemäß dem Flächenlayout unseres Geräts. Wir werden erfahrenete Techniker entsenden, um das Gerät zu installieren, einzurichten und testweise herzustellen, damit das Gerät die vorgesehene Produktionskapazität der Produktionslinie erreicht.

Ausbildung

Unsere Firma bietet technische Schulungen für unsere Kunden an. Die Schulung umfasst die Struktur und Wartung der Ausrüstung, die Steuerung und Bedienung der Ausrüstung, erfahrene Techniker werden leiten und das Schulungsprogramm aufstellen. Nach der Schulung können die technischen Mitarbeiter des Käufers die Bedienung und Wartung der Ausrüstung beherrschen, den Prozess anpassen und mit verschiedenen Fehlern umgehen.

3.Nach dem Verkauf werden Qualitätsprobleme innerhalb von 2 Stunden beantwortet, falls Telefon- oder Videoleitungen das Problem nicht lösen können, schicken wir innerhalb von 24 Stunden Ingenieure zum Ort, um das Problem zu lösen (in China).

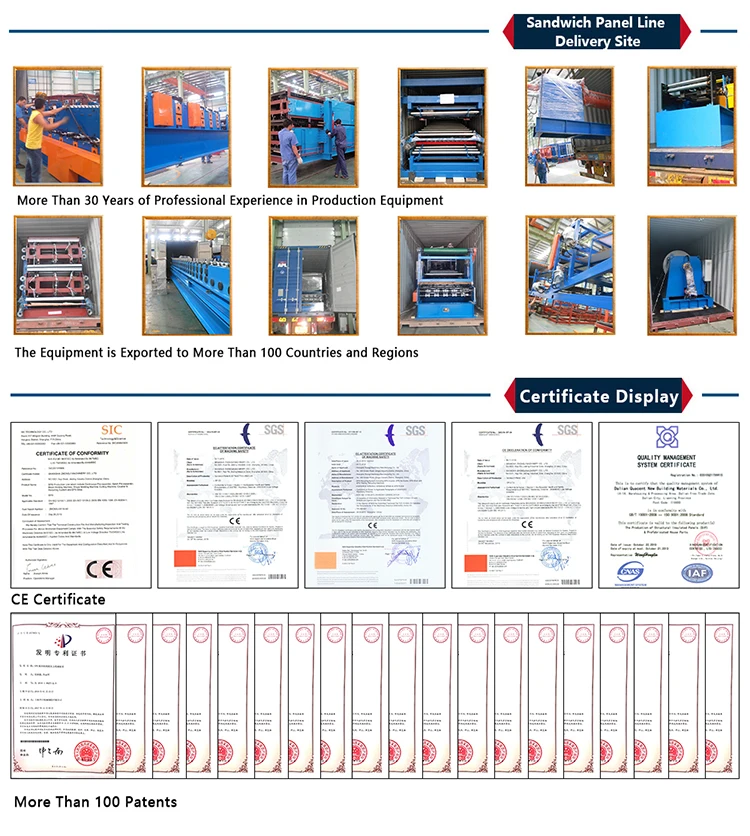

4. Fabrikdirekt Preisnachlässe, 40.000 Quadratmeter Fabrik, 20 Jahre Exportunternehmen, CE-Zertifizierung, mehr als 100 Patente.

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ