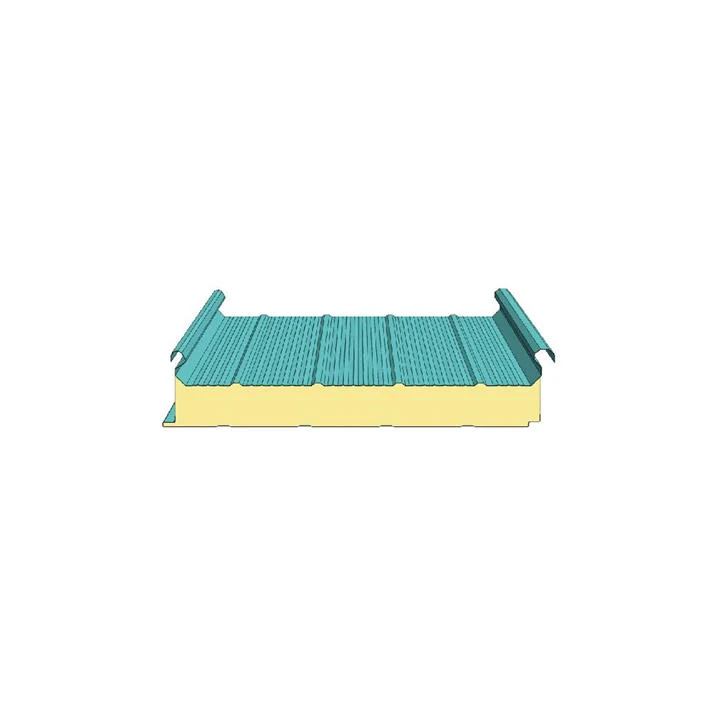

Mineral Wool Sandwich Panels Well, they are the only best building materials which have helped us a lot in making our buildings better than ever. The fixing Eps Panel of real sandwich panels has three layers, like a sandwich. The exterior is composed of two layers of metal sheet and an intermediate layer of mineral wool insulation. This new material is turning the way in which we construct upside down, making buildings more resilient and also energy efficient.

What is Mineral Wool Sandwich Panel Line? or How To Manufacture The Same? The machine has multiple parts, each of which do a separate job. The machine is fed from a large roll of metal coil in the first part. Then, the metal is washed to eliminate any kind of dirt and after that it is treated with a special primer which assists shield.

EN

EN

AR

AR BG

BG HR

HR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA GA

GA BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE MY

MY KK

KK TG

TG UZ

UZ