About Us

Who We Are ?

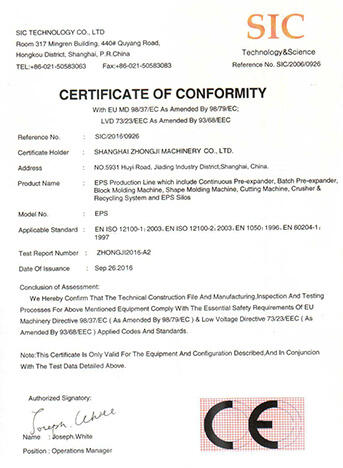

Shanghai Zhongji Machinery Co.,Ltd. was established in 1992. Mr. Hou Shuqi,the chairman of the company,currently serves as the vice president of the China Federation of Private Enterprises. The company has been awarded the title of National High tech Enterprise and has been recognized by the Ministry of Commerce as a designated equipment export manufacturer. It has also led the development of the national standard for 3D steel wire mesh sandwich panels. It is a high-tech group enterprise integrating independent research,development,production,sales and service of continuous production line of polyurethane (PU)/rock wool/EPS color steel sandwich panels,continuous production line of polyurethane/phenolic foam insulation panels,automatic production line of purified color steel sandwich panels,cold bending molding equipment,and continuous production line of EPS/EPP foam plastics. The EPS machine is completed using European technology,with high standards,energy saving of 40% -50%,and very fast cycle time,making it a high-level machine in China. The company has two factories in Qingpu District and Jiading District of Shanghai,with more than 300 employees and more than 80 employees with intermediate or higher professional titles. The factory covers an area of 40000 square meters.

EXPLORE MORE